Toggle Navigation

Cut to length production line

This simple cut to length line is mainly used for terminal customers convenient processing production Simple operation, convenient maintenance

The product feature is as following :

1. The design of the whole machine is reasonable, compact, high precision, high efficiency, flexible and convenient to adjust.

2. Function: Automatically detect steel coil parameters, one-button scrolling, one-button reclaiming, and automatic adjustment.

3. The manufacturing process of the whole machine is strictly in accordance with the mechanical standard specifications, and the production and manufacture of each component is tracked and controlled.

4. Cooperation with well-known domestic and foreign manufacturers, the introduction of first-class leveling technology, and on this basis by professional technical team to develop and extend.

5. The bearings and slide rails of the main engine are imported brands, with advanced lubrication system and long service life.

6. Electrical components are selected from imported high-end brands, and mechanical parts are well-known brands at home and abroad.

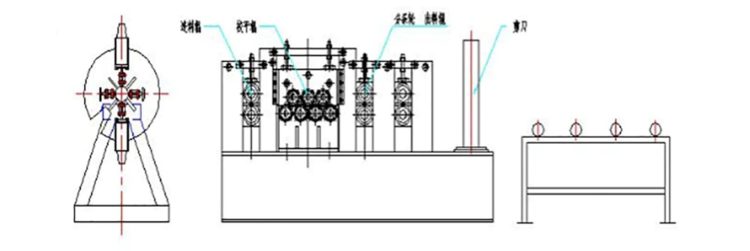

The work flow of the cut to length production line

Uncoiler — Feeding — Leveling — Straightener — Measuring shears — Output table

Product Paramenters

| 1 | Materials | PPGI, GI, Aluminum, Carbon steel, Hot Rolled, Cold Rolled, Stainless steel |

| 2 | Thickness | 0.3-1.5mm |

| 3 | Width | 1250mm |

| 4 | Coil I.D. | 508mm |

| 5 | Coil weight | 5-10Tons |

| 6 | Max speed | 0-15m/min |

| 7 | Cutting precision | 1.0 mm/two meters 0.5mm/one meter |

| 8 | Length tolerance | ≤±1mm/2000mm |

| 9 | Power |

380V/50HZ/3PH(Customized) |

Main Items

| Name | Quantity |

| Coiler car | 1 set |

| Decoiler | 1 set |

| Side guide | 1 set |

| Straightener | 1 set |

| Measuring Hydraulic cutting | 1 set |

| Unloading table | 1 set |

| Motor | 1 set |

| Hydraulic unit | 1 set |