Toggle Navigation

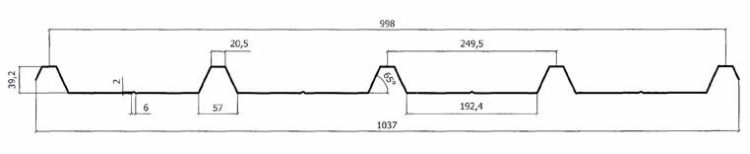

TR40 Steel Roofing Panel is very popular in Peru market, it is available in many colours and thicknesses of galvanized steel. This structural and material design is suitable for exterior cladding of buildings and for pitched roofs of administrative, industrial and commercial buildings. TR 40 is an interesting solution for all surfaces with the possibility of individual design. All your requirements are tailored literally to the unique requirements of each company.

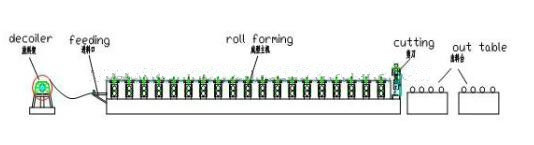

We customized the roof forming machine to make TR40 sheet to meet the customers’ demand. The machine we equipped with manual decoiler, roll forming system, hydraulic shearing system, PLC control system and output tables. It is a completed production line to help users to produce TR40 sheet smoothly.

1. Processing flow diagram of machine:

Decoiler→ Feeding →Roll forming →Measure length →Hydraulic cutting →Output table

| Manual decoiler | |

| Capacity | 5ton |

| Feeding width | MAX 1300mm |

| Expanding range | 460-520mm |

| TR40 Steel Roofing Panel Making Machine Roof Sheet Roll Forming Machine Export to Peru | |

| Main motor power | 5.5kw |

| Drive | 1” single chain |

| Type: | Wall board |

| Main shaft dia | ¢70mm |

| material | 45# forge steel and quenched |

| Roller material | 45# high grade forge steel ,chrome coated 0.05mm |

| Roll station | 16 groups |

| Raw material | 0.3-0.7mm |

| Coil width | 1250mm |

| Working speed | 10m–15m/min(Exclude cutting time) |

| Length Tolerance | ±1.5mm |

| Weight of machine | About 5 ton |

| Size of machine | About 8500×1800×1500mm L x W x H |

| Color of machine | Yellow and Blue |

| Coder | Omron, made in Japan |

| Control | PLC Panasonic, made in Japan. 380V 50HZ,3phase (Also depend on client) |

| Computer operating panel | touching screen |

| Other electrical element | Schneider |

| Cutting | Hydraulic cutting. Auto cutting when reach the set length |

| Hydraulic power | 3KW |

| Blade material | Cr12mov,quenched 58°-62° |

| Working pressure | 16mpa |

| Cutting tolerance | +/- 1.0mm |

1.The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connectors are screw which make the machine flexible and stronger.

2.All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

3.We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

Photos of TR40 Steel Roofing Panel Making Machine Roof Sheet Roll Forming Machine Export to Peru for Reference: