Toggle Navigation

TR4-36 metal roofing sheet rolling forming machine for Peru for wall and roofing system

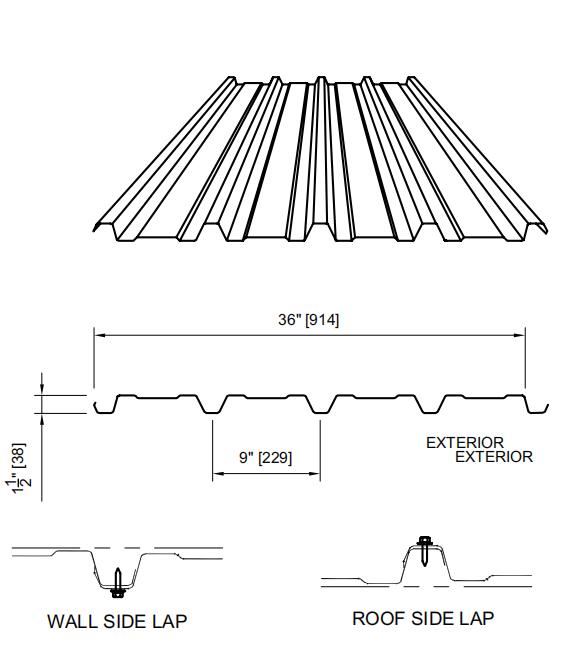

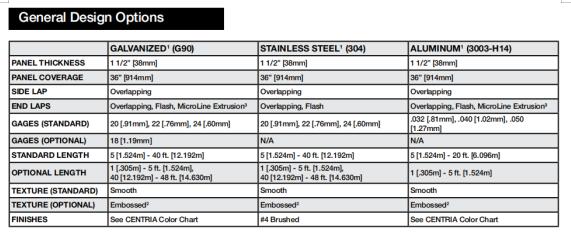

The TR4-36 profile features four 1 1/2” [38 mm] deep ribs on 9” [229mm] centers which gives an attractive, standing rib appearance. TR4-36 side laps in the high cell when used as a wall or roof panel.All Exposed Fastener wall panels may be installed in a variety of rainscreen applications

to form a complete wall system. This profile is quite popular in South American.

Here is the TR4-36 drawing profile for your reference:

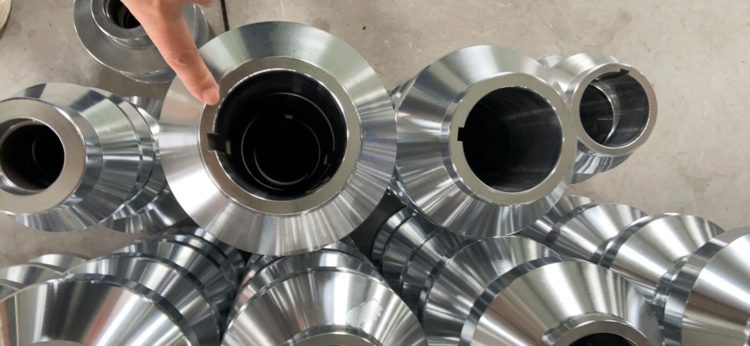

TR4-36 metal roofing sheet rolling forming machine

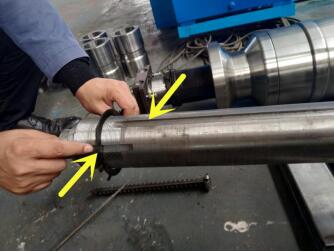

This machine is designed based on knowing fully requirements of this Tr4 drawing profile. The metal roofing sheet machine, we design like this:

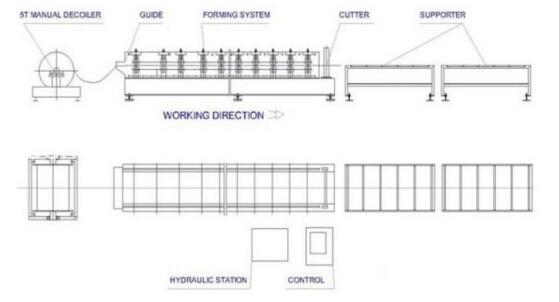

Processing flow diagram of Tr4 metal roofing sheet machine:

Decoiler→ Feeding →Roll forming →Measure length →Hydraulic cutting →Output table

2.Technical parameters for Peru Tr4 Trapezoidal Metal Roof Sheet Roll Forming Machine :

| Article No. | Item Name | Specification |

| 1 | Width of feeding material | 1000 mm coil sheet |

| 2 | Thickness of feeding material | 0.3-0.8 mm coil sheet |

| 3 | Roller station | 19 stations |

| 4 | Shaft Diameter | 90 mm |

| 5 | Productivity | 55 m/min |

| 6 | Rollers’ material | Gcr15 quenching with 0.1 mm chrome |

| 7 | Shaft material | 45# steel with 0.1 mm chrome |

| 8 | Weight | 7 tons |

| 9 | length | 7.5 meter |

| 10 | Voltage | 220V 50Hz 3phases |

| 11 | Control | Portable PLC |

| 12 | Decoiler | 5 tons |

| 13 | Motor | 5.5 kw |

| 14 | Driving way | Chain transmission |

| 15 | Chain size | Double chain |

| 16 | Cutting system | Hydraulic cutter with two hydraulic Jacks |

Why Zhongtuo metal roofing sheet machine is different with others?