Toggle Navigation

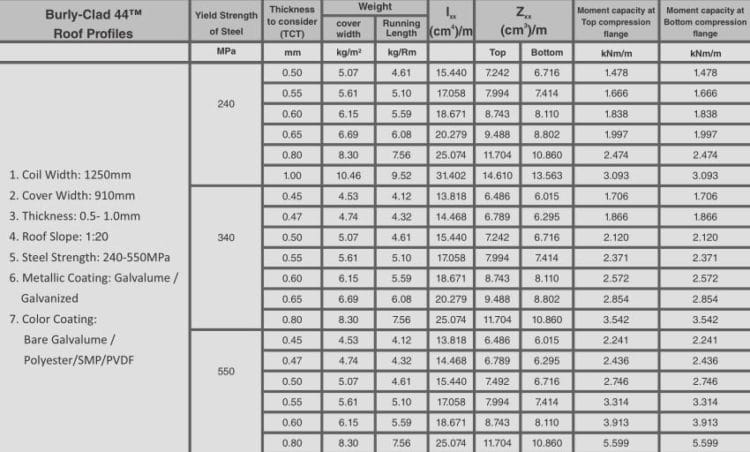

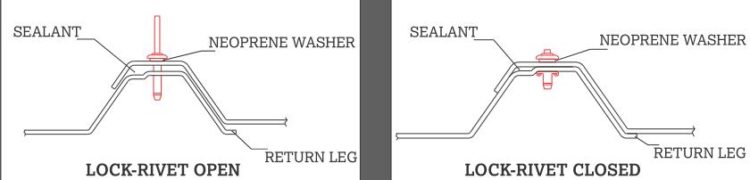

Advantages of Strongest Screw-down trapezoidal roofing sheet:

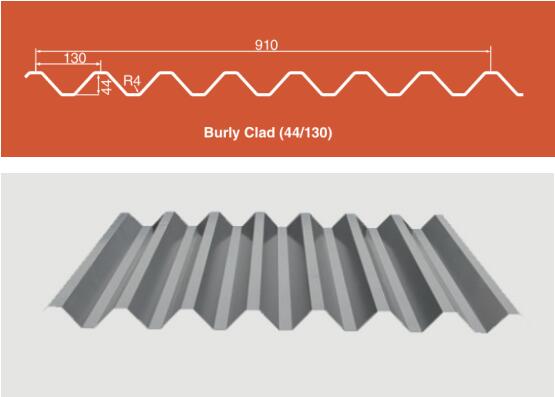

Based on the features of Strongest Screw-down trapezoidal roofing sheet, we design the rolling forming machine like this:

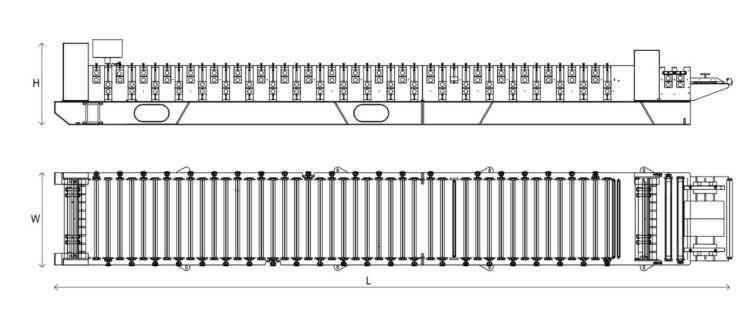

Machine layout for your reference:

Machine specification

Rolling speed“12-14 m/min (EECO) 18-20 m/min (Eco, standard)”

Electric power: 3.7 kW-11 kW

Machine Weight: 7.0-13.0 tons

Dimensions (L x W x H)9.0 m x 1.8 m x 1.5 m

Station Quantity: 18-24 stations

Steel Thickness: 0.2-0.8 mm (BMT), MaterialGI, GL, PPGI, PPGL

Coil Width: 914-1450 mm

Material Strength: G300-G550

Production specification

Control System: PLC, Touch Screen HMI

Transmission System Hydraulic, or Gear motor driven by Inverter

Cutting and Pressing System

And for this machine, if you want to know more information, please contact us at any time.