Toggle Navigation

Storage large diameter corrugated steel pipe/steel granary rolling forming machine

A steel granary is a storehouse or room in a barn for threshed grain or animal feed. Ancient or primitive granaries are most often made out of pottery. Granaries are often built above the ground to keep the stored food away from mice and other animals. Zhongtuo Storage large diameter corrugated steel pipe/steel granary rolling forming machine is designed to make storage large diameter corrugated steel pipes in batch fully automatically.

CORRUGATED SHEET CURVING MACHINE, SHEET BENDING MACHINE, SHEET ROLLING, SILO MAKING MACHINE, CORRUGATED DRUM MAKING, GALVANIZED DRUM MAKING MACHINE, GALVANIZED SHEET BENDING/CURVING MACHINE

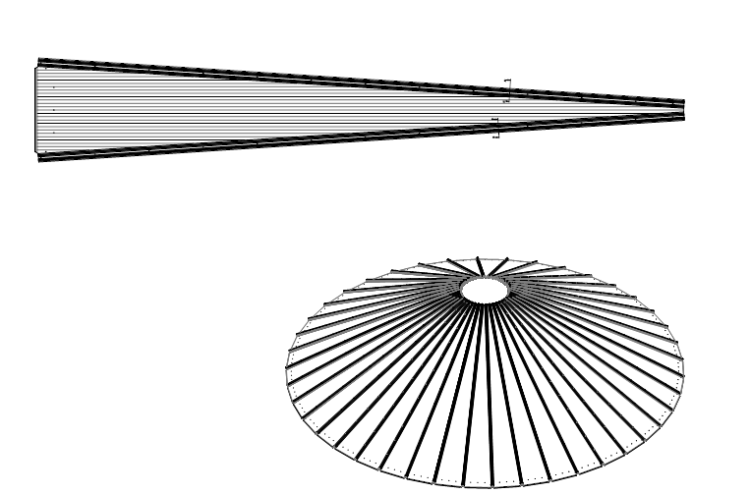

Here is steel granary for your reference:

Steel granary rolling forming machine

Steel granary rolling forming machine supported material:

Thickness: 1,0-2.5mm

Minimum yield strength: 345 MPA

Minimum tensile strength: 450 MPA

Minimum elongation in 50 mm is 12 percent.

Galvanizing Standard: G90 (Z275), G115 (Z350), G140 (Z450)

Corrugation profile:

Length of the sheet walls have to be adjustable by PLC.

PLC has to count produced sheet wall quantities.

All bearings will be SKF or FAG.

Design: According to the designed agreed drawing by both sides.

Steel granary rolling forming machine Roll former:

Design: According to the designed agreed drawing by both sides.

Guiding and feeding rollers: included.

Stations: 18-24 pcs

Upper rollers have to be adjustable according to different material thickness

Digital Guiding scales for adjustment will be located at all stations.

All rollers will be coated with crom.

Last 2 stations are designed for modifying different material thicknesses.

1 more station will be added at front side for feeding.

Precutting will be added. Speed: 10-15 m/min.

Driven: By shafts for all rollers.

Cut to length: will be flying model and cut sheets have to be count by PLC.(you can choice)

Length of sheets have to be adjustable by PLC.

Cut to length Tolerance limit: 0,5-1,0 mm

PLC brand: Panasonic

Electrical material brands: Panasonic.

Roller material: A2; GR15; Carbonization. 58-62degree fire treated

Machine dimensions : About 11.8×1.8×1.4m

Machine weight:About 13 tons

Motor brand: Siemens

Top Panel Roll former:

Guiding and feeding rollers: included.

Speed: 15 m/min.

Driven: By chain system.

PLC: Panasonic

Electrical materials: Panasonic.

Roller Material: A2; GR15; Carbonization. 58-62degree fire treated

Dimensions: about 9×1.6×1.4m

Weight: about 8tones

Hydraulic power: 7.5Kw

Motor brand: Siemens

Hydraulic station brand: Wansheng from Wuxi China

Shearing: Stop shearing type

Hydraulic power: 3.7kw

All bearings will be SKF or FAG brand.

Storage large diameter corrugated steel pipes have other functions:

As to the related elements:

Steel granary rolling forming machine HYDRAULIC DECOILER: You can choose to use the manual one or hydraulic decoiler, as the following picture shows:

As to the stacker:

All those elements are optional.

If you want to know more details, please contact us at any time.

wechat/whatsapp:+8615613740026

Email: cnzt007@zhongtuocn.com