Toggle Navigation

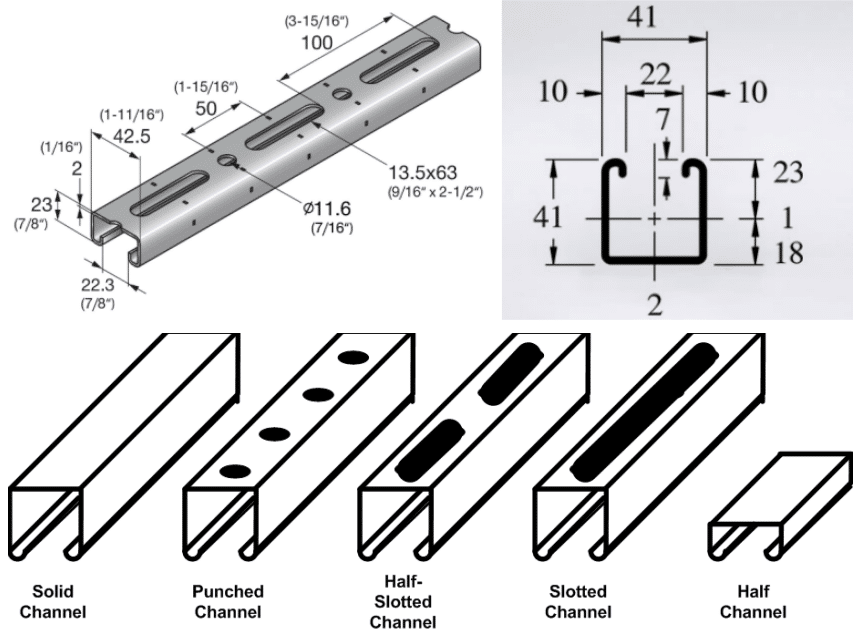

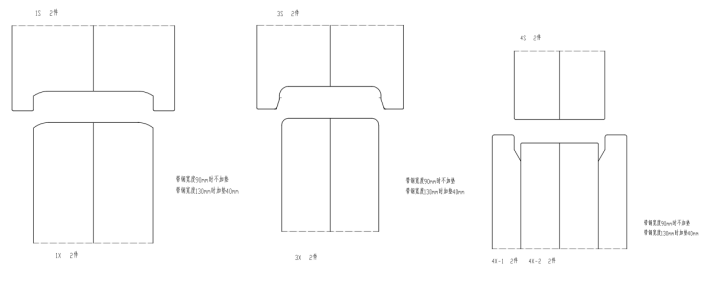

Steel Slotted Strut Channel Rolling Forming Machine is designed for making strut channels in batch fully automatically. Standard structural component generally used for the support of electrical or plumbing products (such as cable tray/ladder, lighting rigs, or pipe clamps), but it also has a wide range of other uses for installing just about anything.41mm slotted channel with punched holes. Galvanized steel for typical outdoor environments. Here is the one drawing profile for your reference:

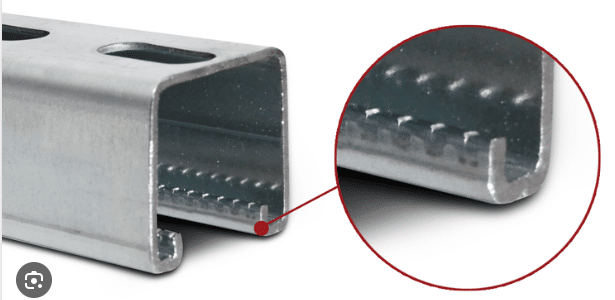

If you need to add the zigzag, we can also add also:

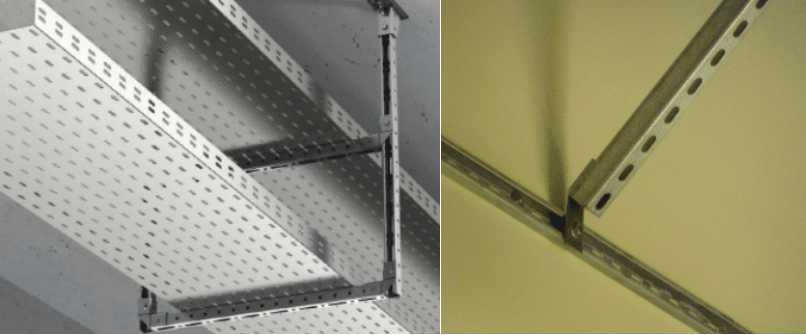

Here are some usage of strut channel:

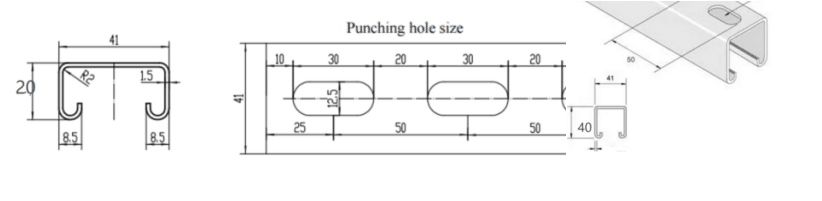

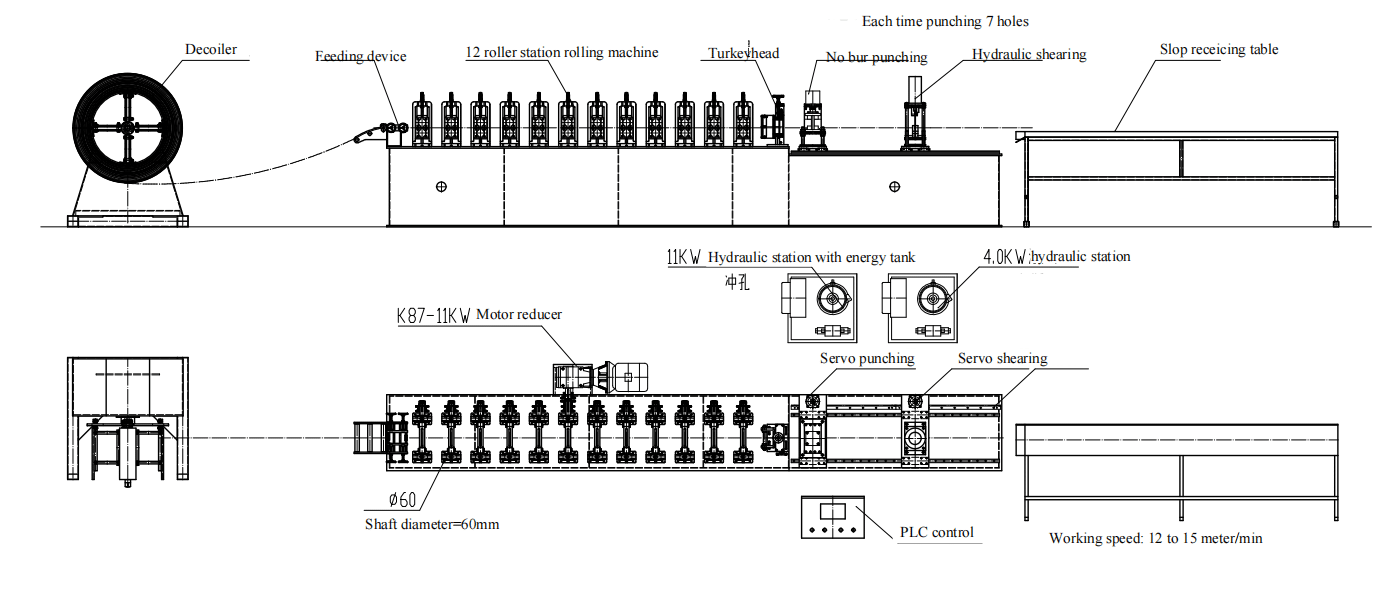

Here I will introduce one type light duty strut channel rolling forming machine:

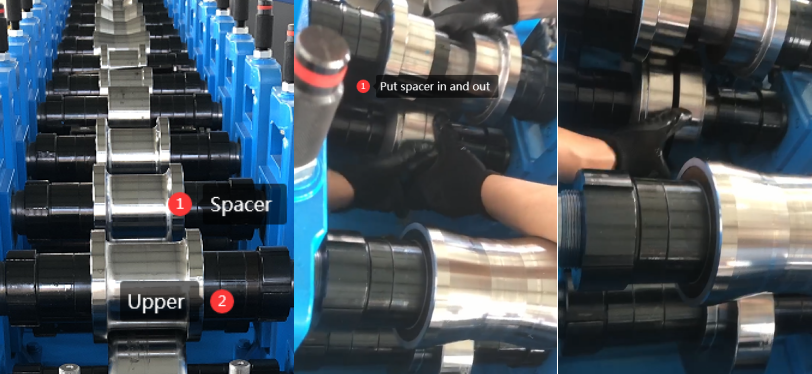

For the sizes adjustments by spacer and change the cutting blade, make sure to be more easier from 41x40 to 41x20: Material thickness: 1.5mm & 1.8mm

Working flow of strut channel rolling forming machine:

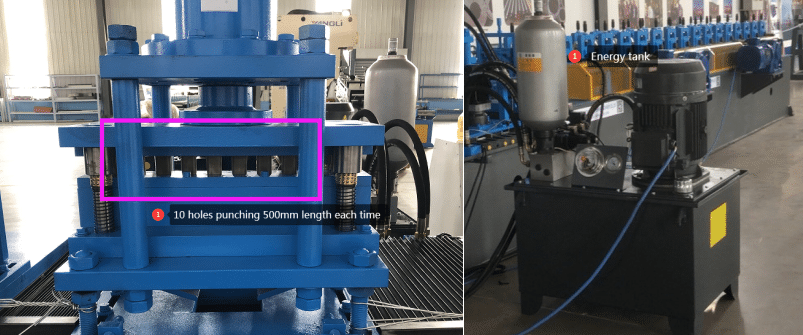

Different the traditional design, this one we use the after punching by servo motor like the following flow.

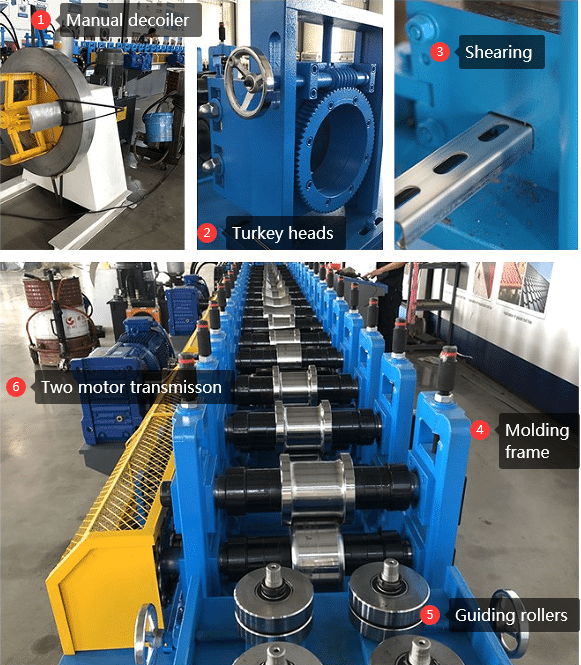

It is composed by the following elements: 3 Ton deoiler, main rolling forming machine with servo punching online and shearing system and the receiving table.

Advantages of light duty strut channel rolling forming machine:

Let us check more details by the following detail pictures:

How to adjust from 41x41 and 41x21mm:

We will give the drawing introduction like and training videos. Normally speaking it needs engineer adjustments around 2 hours.

So you need to adjust the spacer for different sizes according to the instruction manual.

Here is the strut channel working videos for your reference:

<iframe width="650" height="450" src="https://www.youtube.com/embed/leqr2fBYzj0?rel=0" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" allowfullscreen></iframe>