Toggle Navigation

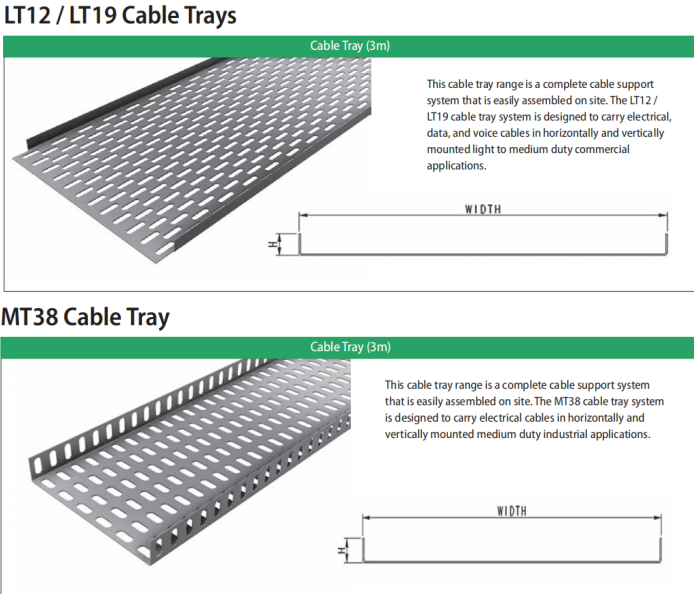

Light duty cable tray rolling forming machine is designed to make the light duty cable trays in batch fully automatically. For the cable tray system is designed to carry electrical, data, and voice cables in horizontally

and vertically mounted light to medium duty commercial applications, up to a maximum width of 304mm.

The LT12 / LT19 cable tray comprises of a flat sheet 3.0m in length, bent to a “U” profile - 12mm high

(up to 76mm wide) or 19mm high (101mm to 304mm wide) to form a rigid channel like support, with Ø 7 x 28mm slotted perforations on the bottom of the tray to allow for air flow throughout the entire installation.

Our cable tray machines could be designed according to the customer drawing profile. You can specify the thickness and width and then we can make the good recommendation.

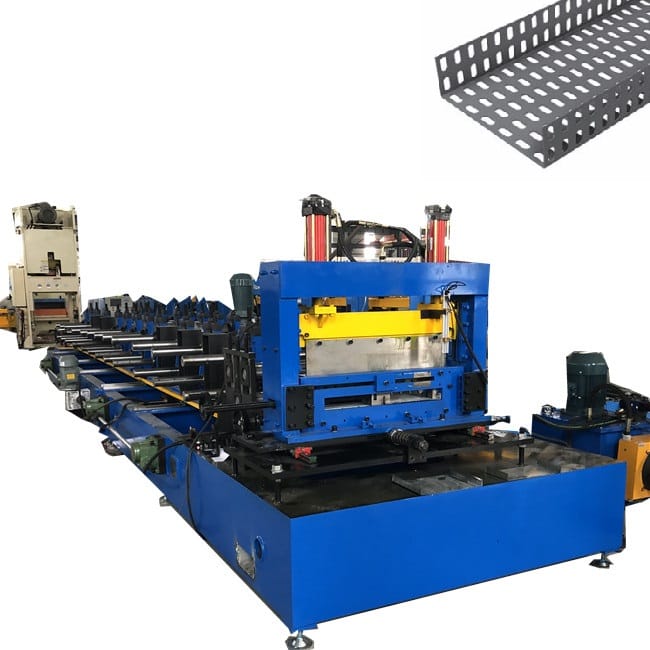

Light duty cable tray rolling forming machine

Design: Normally for producing 50-100mm bottom width by changing spacer manually and another machine produces 100-600mm by big machine. The reason of this design is because the width between 50mm and 600mm is too big distance.If you use one machine to produce from 50-600mm,the roller will be very small,it is not strong enough to produce 600mm big size,the life time of the machine will not long.

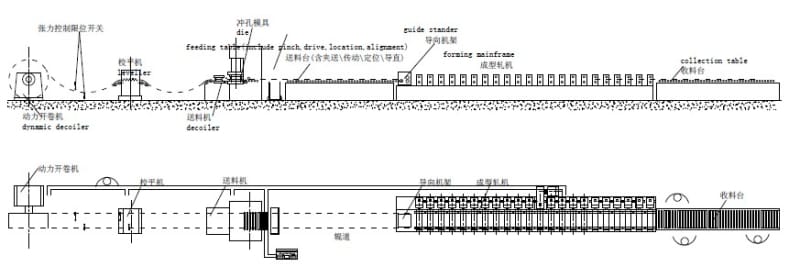

Layout of the cable tray machine:

Automatic decoiling→leveling→servo feeding→punching→cutting→conveyor→roll forming→receive table

More details of all elements of cable tray rolling forming machine:

First Part: Hydraulic decoiler

As default, we recommend 5 Ton hydraulic decoiler with the loading car. With accurate leveling system and then it can make sure feeding the coil into the machine smoothly. By the leveling system, it can adjust to feed different thickness coil better.

Part Two: 215 punching machine.

This part is optional, if you do not have speed requirements, you can use the hydraulic station to punch.

But CNC punching machine, more steady and more stable and speed will be more faster. As to the punching mold, we can design using the combined type mold, normally speak 4 to 5 sets mold that can satisfy the range of bottom width 100 to 600mm width.

Part Three:Main rolling forming machine to make cable tray.

For the width and height adjusted by PLC.

|

Machine type |

Double cantilever gear drive, width adjustable, universal molding machine moves as a whole, can quickly (waist height and width) exchange specifications; |

|

Functions and structure |

Composed by AC motor,speed reducer,high precision guide,left and right gearbox,horizontal adjusting mechanism and rollers.The main machine’s structure is manufactured with Italian imported technology, with higher precision. |

|

Size changing type |

One set of rollers can produce all the sizes,changing sizes by adjusting the frame |

|

Roller station |

18 stations |

|

Roller material |

Gcr15 with forged treatment,quenched treatment after CNC processing, the hardness is HRC58-62.High strength,high hardness,high precision and long time usage. |

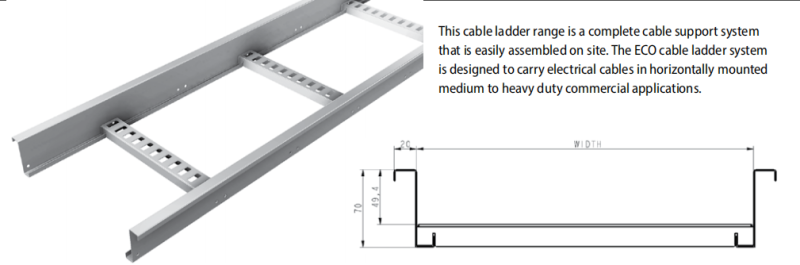

We can also make other types cable tray machines, simple show us more drawing profile and then okay.

Welcome to contact at any time.