Toggle Navigation

Raw Material:

All of our machine profile is customized, above raw material is only for your reference.

Layout:

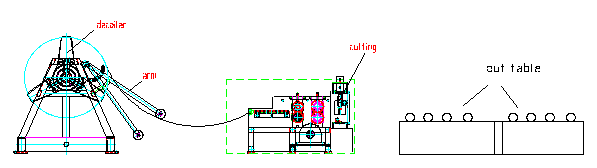

Manual de-coiler—Feeding—Cutting—Out table

Specifications:

| Item NO |

Description |

Offered specification |

| 1 | Roll Forming Machine |

Cut to Length Machine

|

| 2 | Coil width | 1200mm |

| 3 | Rolling Speed | 12-15m/min(not include cutting time) |

| 4 | Rolling Thickness | 0.8-1.5mm GI |

| 5 | Control System | PLC (Panasonic) as list in the note |

| 6 | Un Coiler | 5T manual de-coiler |

| 7 | Roller Stations | 2 stations for feeding |

| 8 | Roller Material | Rubber roller |

| 9 | Shaft Material and DIA | ¢85mm, material is 45# forge steel |

| 10 | Slitting | Maximum in 6 strips |

| 11 | Blades of slitting | 5 sets of slitting |

| 12 | Post cutting | Hydraulic cutting slitting |

| 13 | Main Motor Power | 7.5kw |

| 14 | Hydraulic Station Power | 5.5kw |

| 15 | Hydraulic Pressure | 12-16Mpa adjustable |

| 16 | Material Of Cutting | Cr12Mov quenching 58-62℃ |

| 17 | Structure Of The Stations | Wall panel |

| 18 | Tolerance | 3m+-1.5mm |

| 19 | Electric Source |

380V, 50HZ,3 phase

According to customer’s require

|

| 20 | Way Of Drive | By chain |

| 21 | Color Of The Machine | Yellow and blue |

| 22 | Size of the machine | L*W*H about 2.0m*1.7m*1.2m |

| 23 | Container Need | 1×20 feet |

Main Features