Toggle Navigation

Brief introduction

The coil metal slitting line is used for coil with different specifications, through uncoiling–slitting–recoiling to any needed width coil for the application of all kinds of welded pip/tube making machine.

The line is reasonable in layout, easy operation, high level of automation, high productivity which could process coil,silicon coil, stainless coil, colored coil,aluminum coil,galvanize coil or painted coil.The line is broadly applying in metal plate processing industry,like car,container, household application, packing,construction material,etc. this line is composed of coil car,uncoiler,slitting machine, scrap recoiler, tension unit,recoiler and unloading coil car, hydraulic system,ec. This line can be adjusted to do recoiling or dividing work to meet customer’s demand.

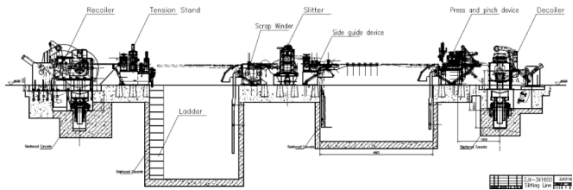

Flowing chart

From right to left are: Entry coil car→Hydraulic decoiler →Hydraulic press and pinch device→Hydraulic cutter→Looper 1→Side guide device→ Slitter→Scrap winder→Looper 2→Tension stand →Recoielr→Exit coil car

Main components

1. Coil car

2. Decoiler

3. Peeler entry table

4. Straightener.

5. Shearing machine

6. Loop table

7. Coil guide and pinch roll

8. Slitting machine

9. Scrap winder (both sides)

10. Loop table

11. Separator and tension table

12. Deflector roll and exit threading table

13. Recoiler

14. Over arm separator in the recoiler.

15. Exit coil car for recoiler

16. Hydraulic system

17. Pneumatic system

18. Electrical control system

The main model you may select

| model | thickness(mm) | width(mm) | number PCS | accuracy(mm) |

speed (m/min) |

weight(t) |

| ZTSL-1×650 | 0.2-1 | 150-650 | 30-8 | ±0.05 | 0-40 | 3,5 |

| ZTSL-2×850 | 0.3-2 | 300-850 | 30-8 | ±0.05 | 0-40 | 10,15 |

| ZTSL-3×1300 | 0.4-3 | 400-1300 | 30-8 | ±0.05 | 0-120 | 10,15 |

| ZTSL-4×1600 | 0.5-4 | 400-1600 | 30-8 | ±0.05 | 0-120 | 15,20 |

| ZTSL-5×1600 | 0.6-5 | 500-1600 | 30-6 | ±0.05 | 0-120 | 15,20 |

| ZTSL-6×1300 | 1-6 | 600-1300 | 30-6 | ±0.05 | 0-120 | 10,15 |

| ZTSL-8×1600 | 2-8 | 600-1600 | 30-6 | ±0.05 | 0-100 | 15,20 |

| ZTSL-10×1950 | 3-10 | 800-1950 | 30-6 | ±0.05 | 0-100 | 20,35 |

Main machine