Toggle Navigation

Simple fully automatic cut to length production line for thickness 1 to 3mm and width to 1500mm. This type cut to length is mainly for cutting the metal to specified length in the speed of 35 to 40 meter per minute. The good thing of this line is, it is simple and easy to use. The most important thing that is cost is not so higher but the accuracy and the speed is nice for normal production.

This machine is made based on the following requirements from clients:

Customer requirements:

Thickness range: 0.30 mm to 3 mm

Coil width: 1500 mm width

Stacker 3.1 meter ( 6100 mm)

Finished product parameters

Shear stacking length: 500 ~ 6000mm

Length accuracy: 0.5mm/2m steady speed 1.0mm/3m variable speed

Diagonal accuracy: 1.0mm/2m

Plate flatness: 1.5mm/m2

Speed: 0-20m / min above 2mm thick; 0-35m / min below 1.5mm thick

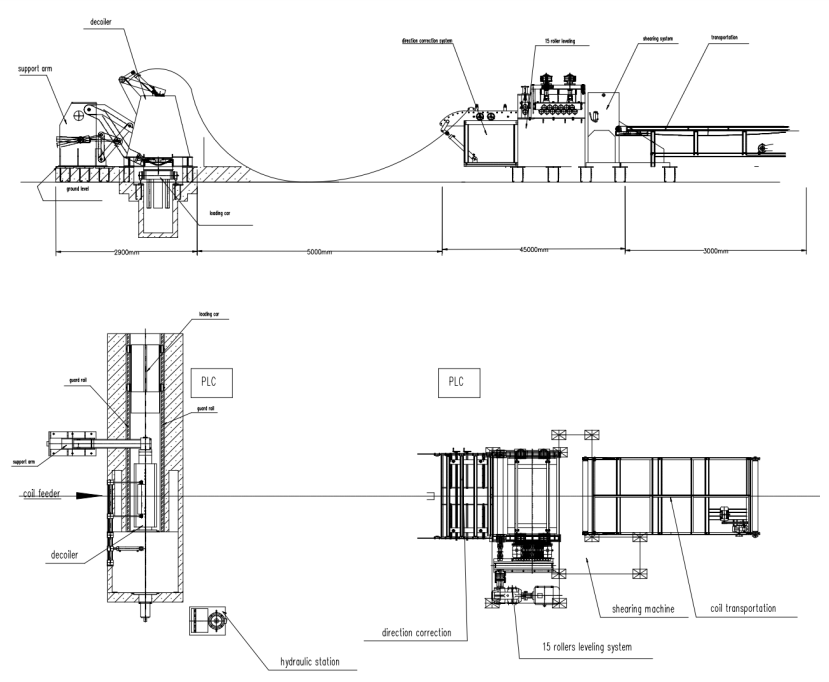

Simple fully automatic cut to length production line

Decoiler -Feeding roller- Leveling rollers - Cutting device- convey - Receiving table

Machine components:

Hydraulic decoiler with loading car 10 Ton : 1 set

Straighten leveling & cut to length machine : 1 set

Hydraulic cutting system: 1 set

Hydraulic station: 2 sets

PLC Control system: 1 set

10 ton hydraulic decoiler

Purpose: active uncoiling and discharging or reclaiming coil materials.

Structure: single drum type.

Inner diameter of coil material: Φ 508mm/ Φ 610mm

Supporting drums, hydraulic expansion. Expansion and contraction range φ 480- φ 520mm、

The drum is driven by variable frequency motor and can be rewound.

Pneumatic disc brake is installed at the end of the main shaft to generate uncoiling tension and brake.

Swing pressure roller is installed above the drum. The pressure roller is wrapped with rubber, electrically rotated and hydraulically oscillated.

Uncoiling motor: 15kw

Uncoiling frequency conversion: 15kw

Expansion and contraction oil cylinder: φ 140x100st, 1

Roller cylinder: φ 100x370st, 2 pcs

Main motor pressurizing arm

Main frame 400 I-beam

30 thick iron plate welding of main body

Main shaft 230 * 65 seamless pipe

Uncoiler with hydraulic automatic support arm

The uncoiler is equipped with hydraulic pressure arm, and the pressure arm wheel is powered by 4kw motor.

Purpose: to level the coil material

There are 15 leveling rollers, 7 arranged at the top and 8 arranged at the bottom (with a feeding shaft), and the roller diameter ф 100, effective roll surface width 1600mm, material 40Cr, high-frequency quenching, hard chromium plating on the surface.

There are 4 rows of short support rollers at the top and bottom, and the roller diameter ф 120, material 40Cr, high-frequency quenching, upper and lower rows of support rollers are adjusted by inclined iron to prevent the leveling roller from being deformed by force.

The machine base is divided into upper and lower parts, which are connected by four strong pull rods. The upper base is used to install the upper row of leveling rollers. The lower base is used to install the lower leveling roller group and support the whole machine body.

The transmission system is composed of motor, hard tooth reducer and gear transmission.

The reducer adopts hard tooth surface reducer. Coupling adopts high-quality ball cage type.

The leveling machine is quadruple, with two auxiliary shafts at the top and bottom.

The motor is 18.5kw Frequency converter: 22kw

The leveler adds a shovel head, and the hydraulic pressure rises and falls.

Purpose: to shear fixed length plates during continuous operation of plates.

Structure: Cutting direction: from top to bottom. The shear is double hydraulic cylinder.

Now in order to enchance the shearing speed, we also give you another design of the servo motor shearing.

Convey table: 6 meter longer Stacker of 6100 meter

For the cut to length machine, we can fully design the cut to length machine according to your requirements, simple tell us the thickness and coil width , speed and Max coil loading weight and then we can make the accurate quotation for you.

But if you need fully automatic production line heavy duty, we can also supply you like the following type.