Toggle Navigation

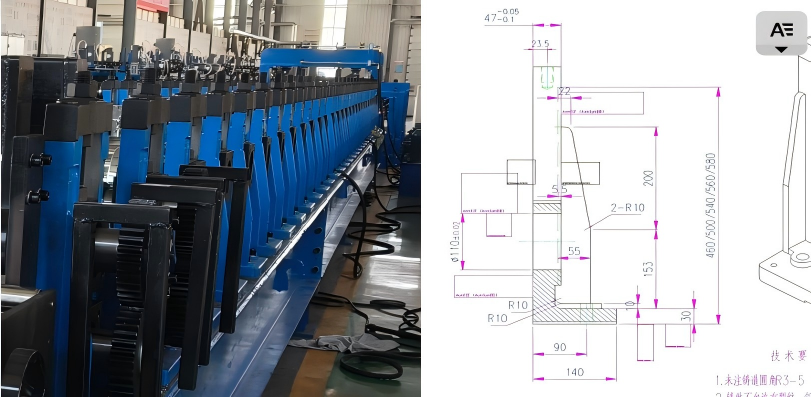

Metal deck roll forming machine is designed to make the floor decking in batch automatically in a high speed. For the metal deck rolling forming machine, we supply the following types:

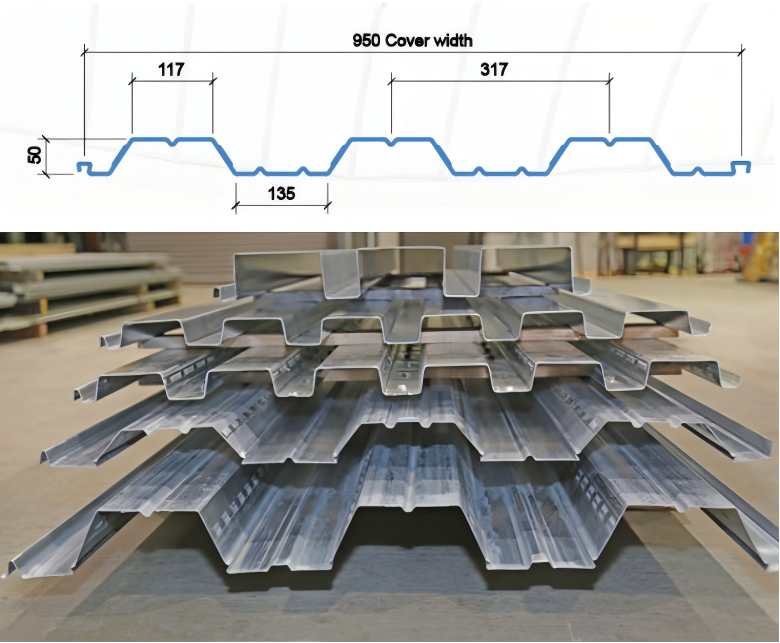

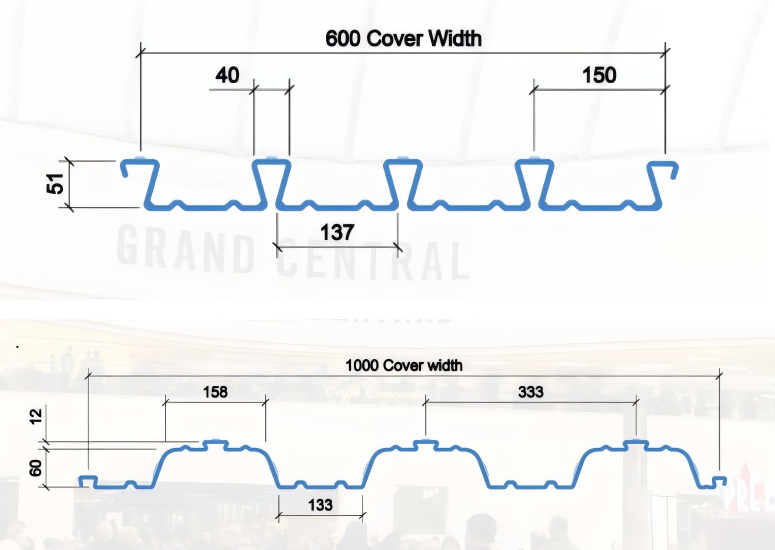

Here we take one drawing profile for your reference: TR50

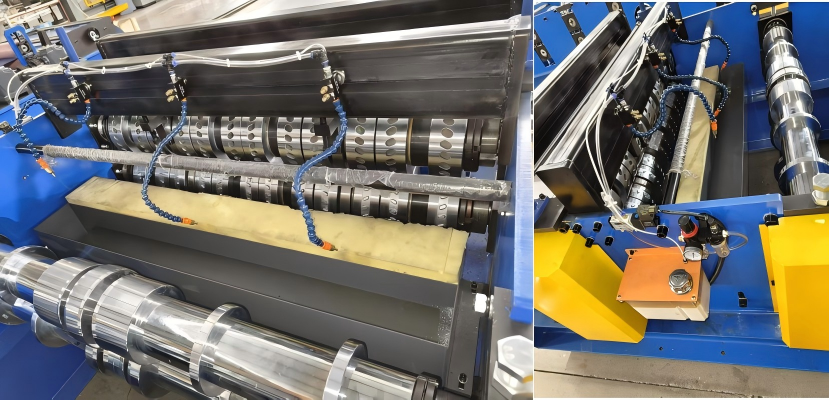

Here is the embossing pattern for your reference:

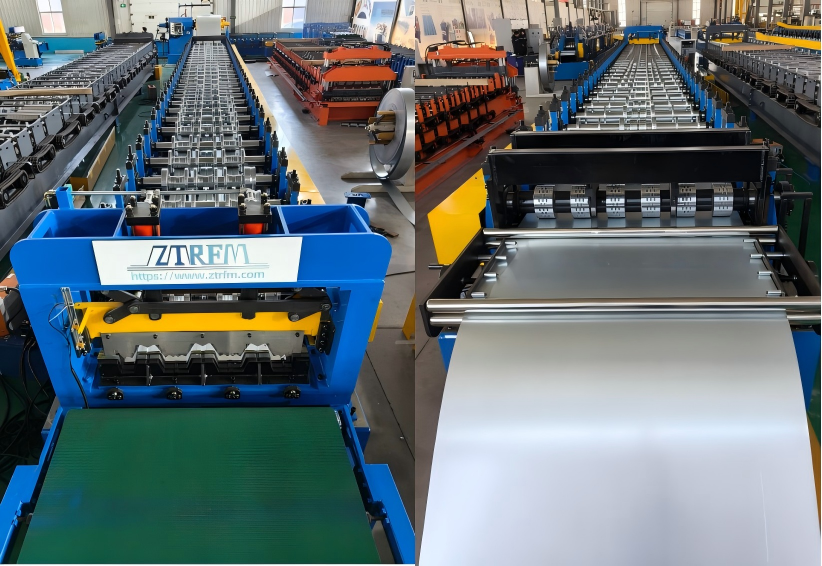

METAL DECK ROLL FORMING MACHINES Design:

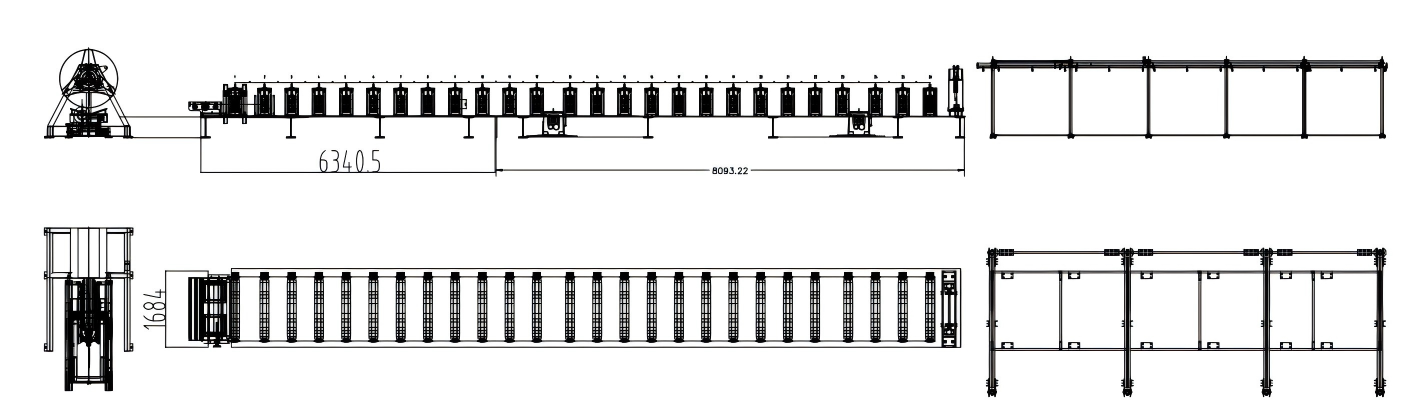

Working Flow of metal decking machine:

Here are some basic parameters of metal decking machine:

|

Rolling shaft material |

45# STEEL |

|

|

Shaft diameter |

115mm |

|

|

Roller material |

45# steel |

|

|

Rolling station |

32 roller station |

|

|

Work speed |

15 t m/min |

|

|

Machine structure |

Molding frame |

45mm thickness |

|

Machine basic frame |

500# H steel welded |

|

|

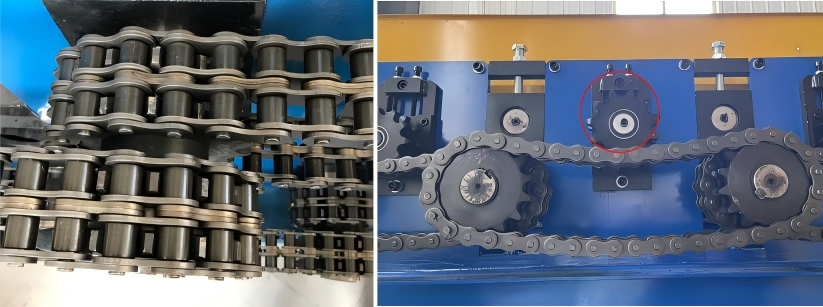

Bearing |

Roller bearing |

Famous brand of Harbin |

|

Work power |

18.5kw x 2 two motors |

|

|

Transmission |

By Chains |

With cover |

|

Motor brand |

Siemens Beide |

|

Features of Zhongtuo Metal Decking rolling forming machine:

There are lot of difference and features, we can not list all of them. Welcome to send inquiry to us.

There are more popular designs of metal decking we could make for your reference:

METAL DECK ROLL FORMING MACHINES Working videos for your reference:

<iframe width="650" height="450" src="https://www.youtube.com/embed/6cCsFA6l_Mk?si=bR_Saf5CsN9y7Yis" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" referrerpolicy="strict-origin-when-cross-origin" allowfullscreen></iframe>