Toggle Navigation

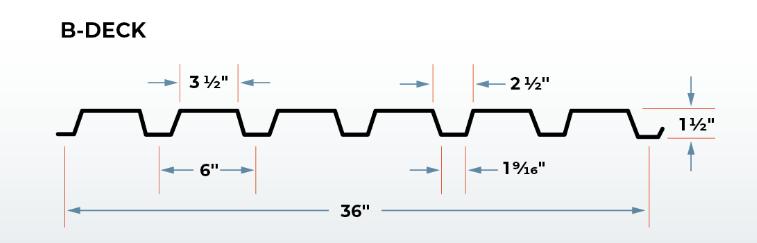

Roof deck Form Deck Composite Deck rolling forming machine is designed for the producing the decking sheet for USA in batch fully automatically. Here are some popular designs in USA for your reference:

B Deck is the most common structural roof deck and provides an economical and easy to install choice.

Roof deck in 22, 20, 18, and 16 gauge. Typically B Decking is the ideal solution for short to medium span applications in roof, canopies, and awning construction. CSM Metal Deck’s B Deck supports construction spans from 1 foot to 11 feet in distance, depending upon the gauge and back-span condition (single, double, triple)

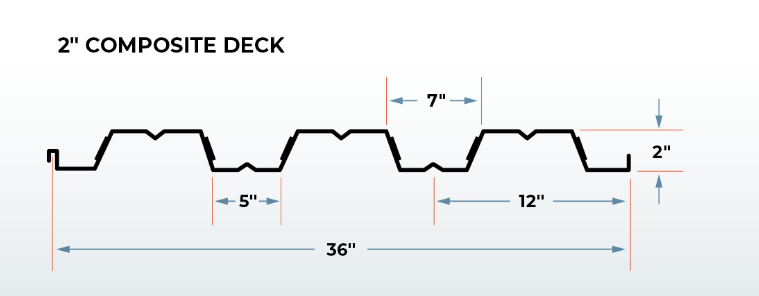

Composite Metal Deck is a durable and easy to install choice for your metal floor decking

1.5″ Composite Deck in 22, 20, 18, and 16 gauge. Typically 1.5″ Composite Deck is used for applications in outdoor flooring. CSM Metal Deck’s 1.5″ Composite Deck supports construction spans from 1 foot to 11 feet in distance, depending upon the gauge and back-span condition (single, double, triple).

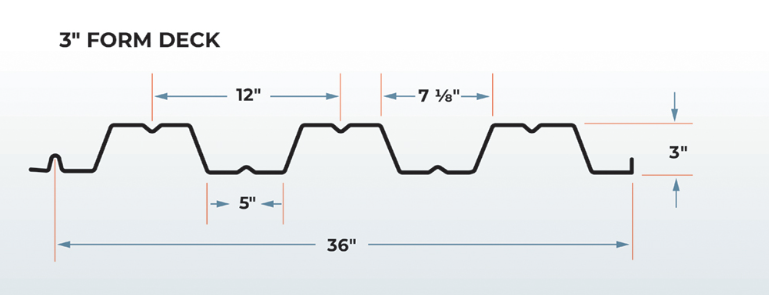

Metal form deck is used extensively in floor construction. Installation is fast, easy, and affordable.

Type 1.5″ form deck in 22, 20, 18, and 16 gauge. Typically Form Decking serves as a permanent steel base for poured, reinforced concrete floor slabs. CSM Metal Deck’s 1.5″ Form Deck supports construction spans from 1 foot to 11 feet in distance, depending upon the gauge and back-span condition (single, double, triple).

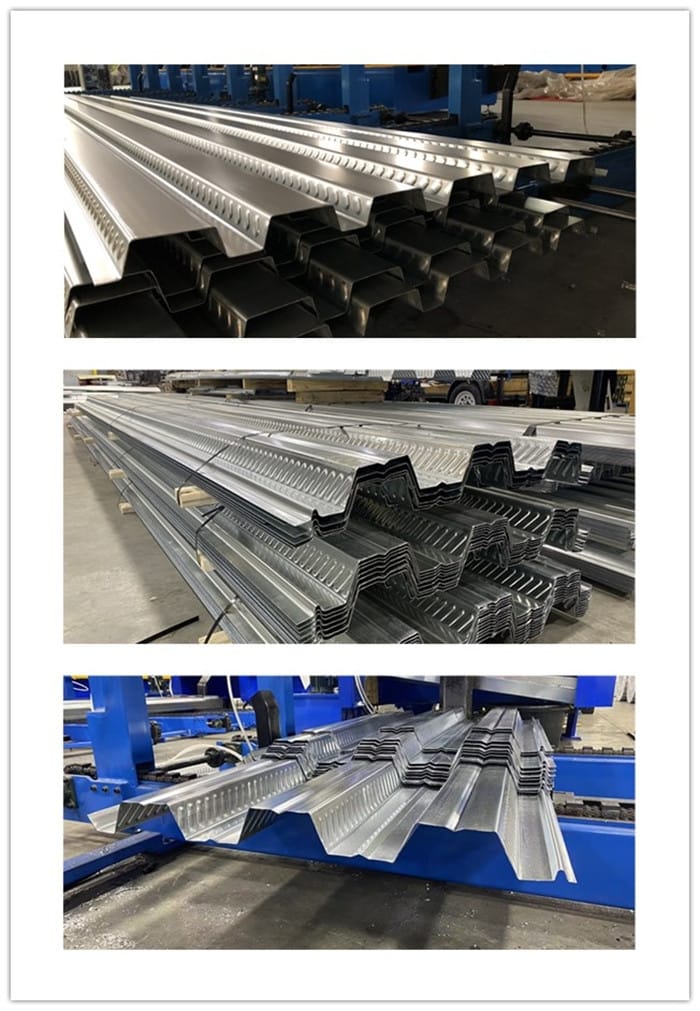

Roof deck Form Deck Composite Deck rolling forming machine for USA

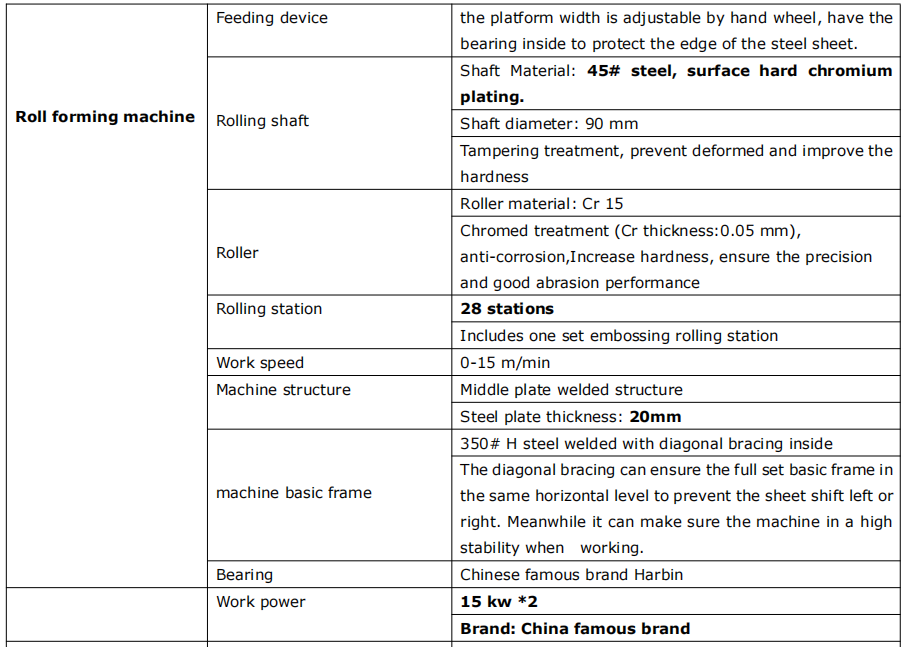

Here are some machine parameters for your reference:

As to the hydraulic decoiler and stacker is optional. Here is the machine working video for your reference

Here is the machine working videos for your reference:

<iframe width="650" height="450" src="https://www.youtube.com/embed/ZnzHnF8jJ4U?rel=0" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" allowfullscreen></iframe>