Toggle Navigation

Standing Seam Roofing Machines with Panel Roll Cutting Forming Machine

What’s standing Roof sheet System?

standing Seam Roof System is a new advanced roof system which seam each other through ribbed metal

plates.The material can be aluminum magnesium manganese alloy plate, can also be aluminum-zinc plate.

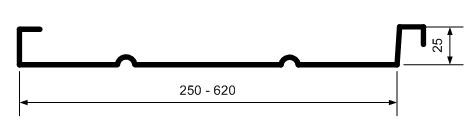

The drawing profile for your reference :

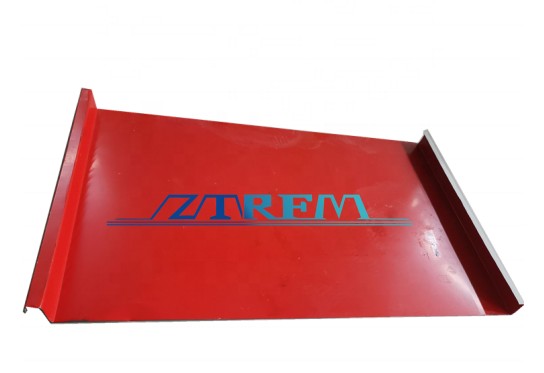

Finished product profile:

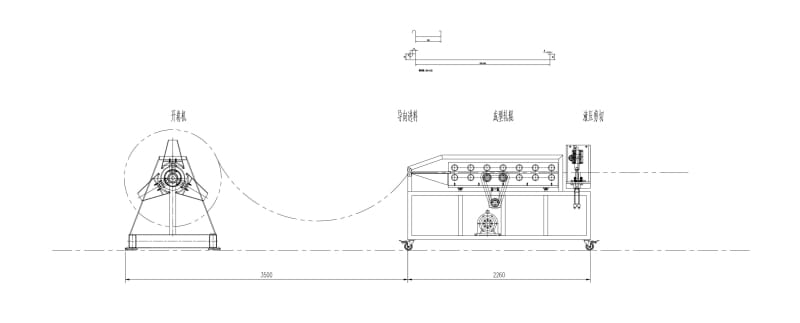

The work flow of the Standing Seam Roofing Machines with Panel Roll Cutting Forming Machine

Based on the customer requirements and our experience,we design theStanding Seam Roofing Machines with Panel Roll Cutting Forming Machine like the following:

The Main Technical Parameters of Portable Standing Seam Roll Forming Machine:

| NO. | ITEM | PARAMETER | NOTE | |

| 1. | Suitable material | Type | Pre-painted sheet, Galvanized sheet | |

| Width(mm) | 1250mm | |||

| Thickness(mm) | 0.3-0.8mm | |||

| Yield stress(mm) | G220-G300 | |||

| 2. | Product specifications | Detail as the attached file | ||

| Length | Any length | |||

| 3. | Power requirement | Type | 380v/3ph/50hz | |

| Main Motor power | 4kw | |||

| Cutter power | 4kw | |||

| 4. | Forming speed(m/min) | 20m/min | Not include the time of cutting | |

| 5. | Manual Decoiler(Optional) | Type | Manual | |

| Max capacity | 5t | |||

| Suitable coil OD(MM) | 1000 | |||

| Suitable coilID(MM) | 508 | |||

| 6. | Forming stand | 18 | Depend on actual design | |

| 7. | Thickness of structure | 16mm | ||

| 8. | Forming shaft diameter(mm) | 70 solid | ||

| 9. | Type of cutting | Roll formed and length-set cutting | ||

| 10. | Control system | Panasonic PLC and inverter | ||

| 11. | Install dimension(depend on the final design) | 9.2m×1.5m×1.3m | Without panel length | |

| 12. | Total weight(Approx) | 5.2T | Depend on final design | |

Where the metal panel is used and how the application scence: