Toggle Navigation

Product Description

The ZT-Prollformer series is a fully mobile pan former ideal for both the workshop and for on-site operation.All functions and adjustments are positioned to one side of the machine. It is easy to transport, light weight with two castors mounted on frame. This saves on freight costs, shortages and the need for difficult leak prone panel end laps.

The guillotine-shear cuts panels without distortion and burr-free.

equipped with 4 crane lifting eyes.

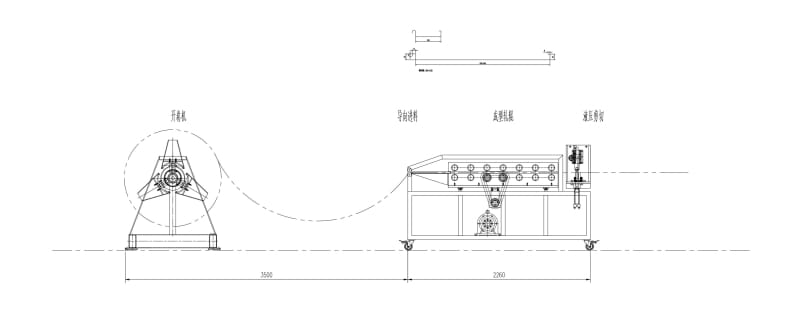

Working flow of Small portable linear roll forming machine for wall panel or roofing sheet:

For this portable machine, you can either use it as the production line or use separately. When working as the production line, the working speed can reach 15 to 25 meter per minute. If you use it as the production line, ZT machinery can supply the hydraulic decoiler and receiving table.

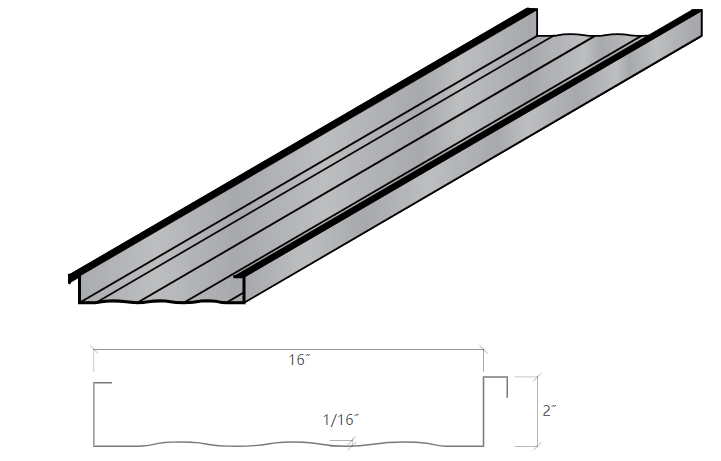

Here are some sample for your reference of portable linear roll forming machine for wall panel or roofing sheet:

How to use in daily life:

How to do the installation of such roofing sheets:

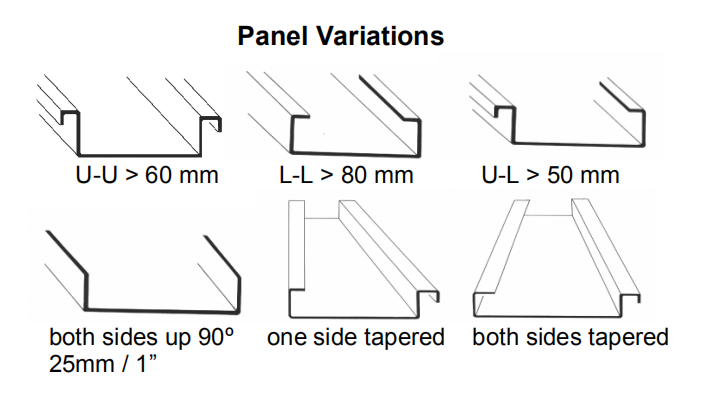

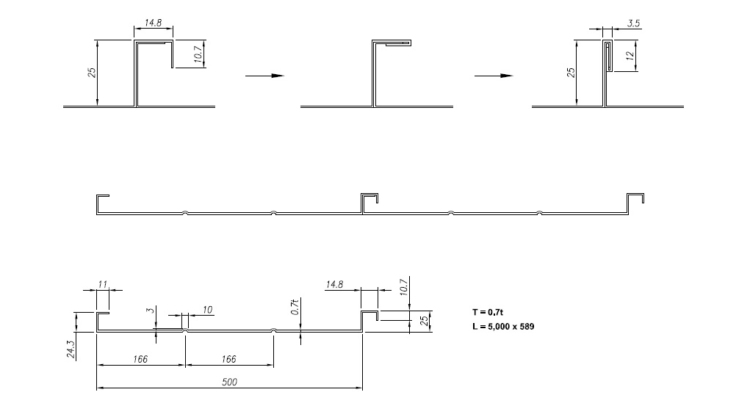

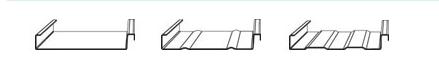

Manual and small portable linear roll forming machine could be used to make roofing panel within width 300 to 1250mm. But this is manual version, so it is easy to put any project on site, you can make any width you need easy. Meanwhile it is portable conveniently. Some drawing profile for your reference:

Material width: 180mm a 1250 mm

Material thickness: 0.5 – 0.7mm

Drawing profile height: 25mm

Working speed: 7 meter per minute

Power: 0,55 kw

Voltage: V 380

Machine size: 1700x940x820mm

Machine weight: 250kg

The machine produces panels for standing seam roof with a double seam. The machine works with all types of roof covering: steel (including polymer-coated), copper (including painted), aluminum, zinc, aluzinc, zinc-titanium. The material may be in rolls or in sheets. Optimized configuration of grading rollers ensures high quality of the profile.

Advantage of Small portable linear roll forming machine for wall panel or roofing sheet

Small portable linear roll forming machine for wall panel or roofing sheet also could be used to produce other profiles like the following drawing profile: