Toggle Navigation

Zhongtuo Metal Step Tile Roll Forming Machine for Mexico market

Features of Zhongtuo step tile rolling forming machine:

In the following part, we will take the Metal Step Tile Roll Forming Machine for Mexico market for an example, to show you how our machine is designed:

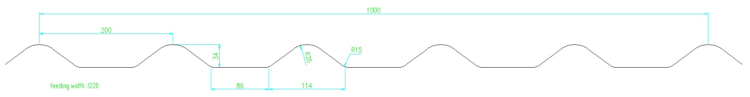

Drawing profile popular in Mexico market:

Finished product pictures:

Zhongtuo Metal Step Tile Roll Forming Machine for Mexico market:

Zhongtuo Metal Step Tile Roll Forming Machine for Mexico market parameters for your reference:

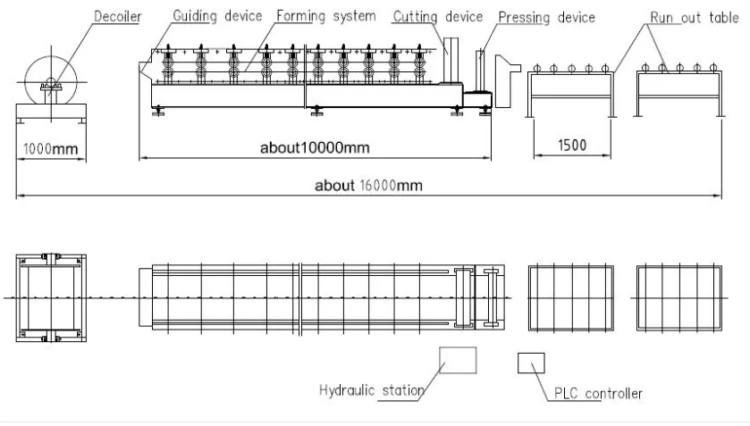

Layout Drawing of Step Tile Roll Forming Machine

| Suitable material | PPGI coils & Aluminium coils ;0.5-0.6mm |

| Working speed | About5- 6m/min |

| Step distance | Adjustable according to requirement (>=250mm) |

| Power Requirement | Main motor power: 5.5 Kw(Depend on final design) |

| Hydraulic station power: 5.5Kw(Depend on final design) | |

| Material of rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter, | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft |

High quality 45# steel, Dia. is 72mm.

Roller grinder milling. |

| Shaft diameter | 72mm |

| Controlling system | Mitsubishi PLC & converter or the brand you specify |

| Total weight of machine | About 9500KGS |

| Machine’s size | About 18m×1.8m× 1.5m (Depend on final design) |

More details of Zhongtuo step tile rolling machines:

As to the PLC part:

Packaging Details:

1. One *40GP container for loading one set of machine with mechanical decoiler;

2.The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3.Spare parts and some small parts packed in plastic tooling box;

4.All Components Fixed by steel wire with Container. Suitable for long time sea shipping.

Delivery Time

Machine ready within 60 days after getting 30% deposit and confirming contract details from buyer and sellers.