Toggle Navigation

Roof Panel Roll Forming Machine For ZT35-117-1000 Profile

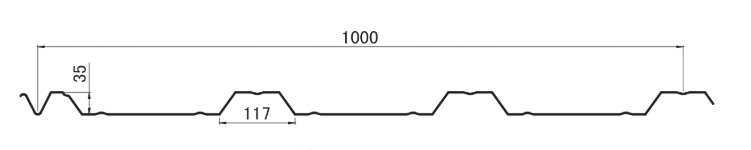

ZT35-117-1000Profile Roof Panel Roll Forming Machine is designed for making the metal roof panel sheet production in batch fully automatically. Metal profile ZT35-117-1000 is designed as:

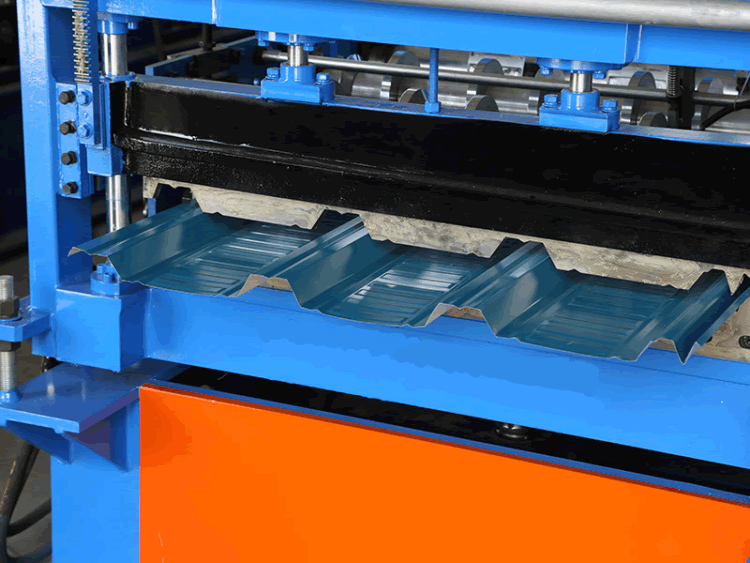

The wave height is 35mm, the wave distance is 117 and the effective width is 1000 and we use the input coil width is 1200mm. And this metal profile is popular in Europe, and other counties.

ZT35-117-1000 Profile Roof Panel drawing profile for your reference:

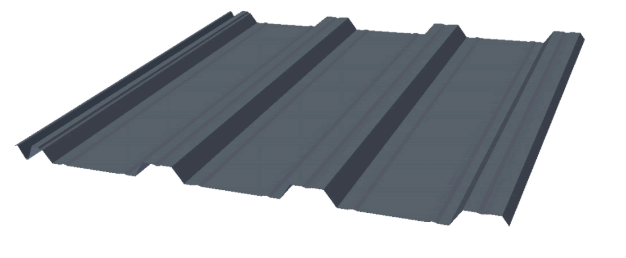

Finished product profile:

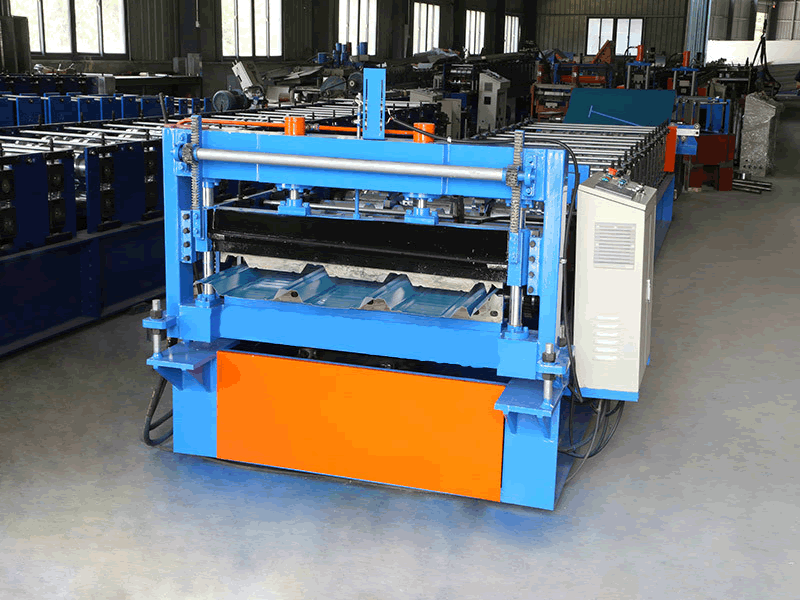

Based on the customer requirements and our experience, we design the ZT28-252-1010 Profile Roof Panel Roll Forming Machine like following picture:

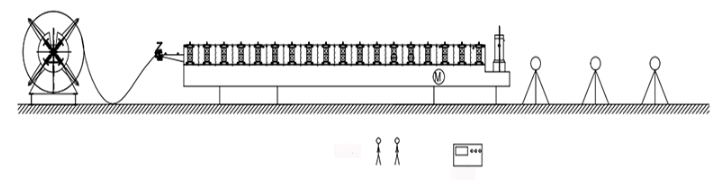

Work Flow of ZT35-117-1000 Profile Roof Panel Roll Forming Machine

Decoiler-→Manual Pre- Cutter-→Guide Feeding -→Roll Forming System- >Hydraulic Post Cutter -→Exit Rack

The ZT35-117-1000 Profile Roof Panel Roll Forming Machine is composed by the following elements:

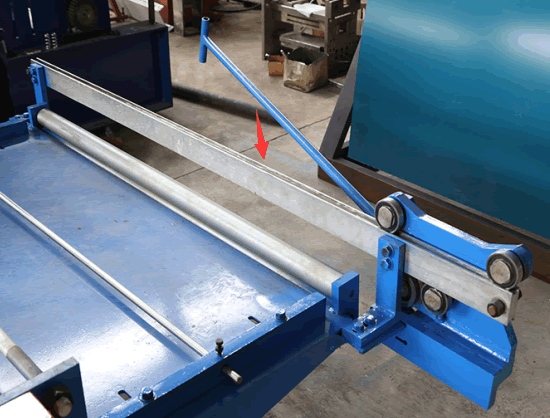

1.Roof panel machine pre-cutter

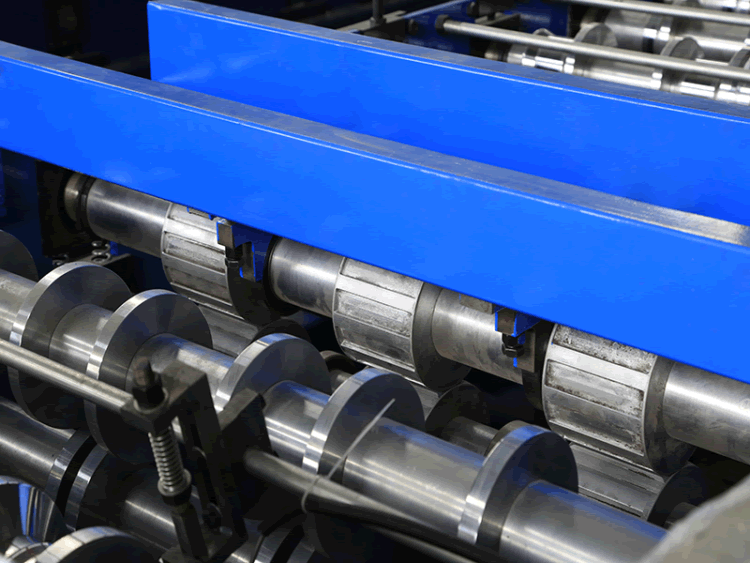

2.Main Machine

With feeding material guide, body frame made from H400 type steel by welding.

Side wall thickness: Q235 t18mm.

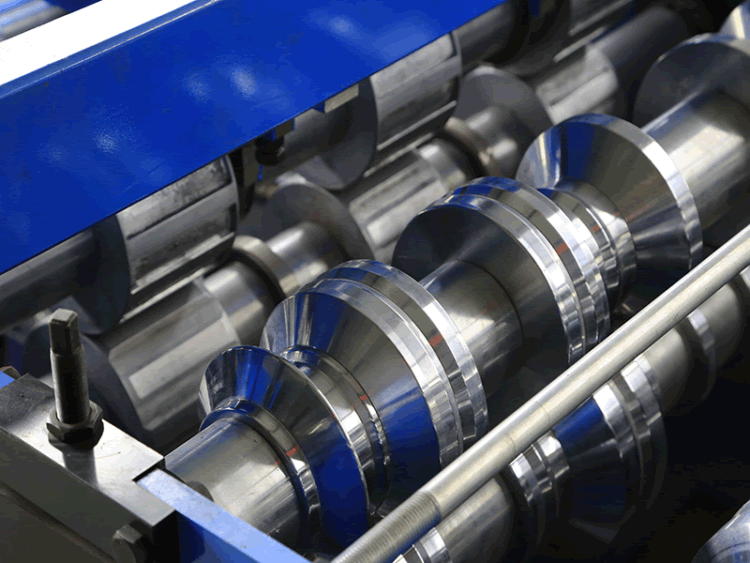

Rollers manufactured from 45# steel,CNC lathes,Heat Treatment,hard Chrome

Coated,with thickness 0.04mm,surface with mirror treatment(for longer life and anti-rust).

Shafts Diameter=q85mm Round steel,precision machined.

Main Motor=7 .5KW,Frequency speed control.

Gear/Sprocket driving,about 18-step to form.

3.Shearing part of ZT28-252-1010 Profile Roof Panel Roll Forming Machine

It takes high quality mold steel Cr12MoV with heat treatment and the frame made from high quality 20mm steel plate by welding. The power we design Hydraulic motor:3KW, Hydraulic pressure range: 0-16Mpa

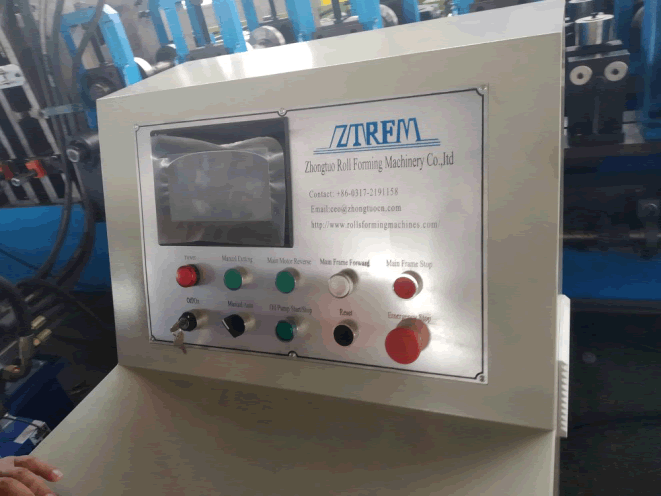

4.PLC operation system:

roof panel machine touching screen and control panel(Button brand :Schneider / screen brand Schneider)

ZT roofing panel machine advantages as follows:

1.Low cost, light weight but high strength, short building period, and re-cycle use

3.Easy operation, low maintenance cost

ZT MACHINE give good after-sale service.