Toggle Navigation

Corrugated steel roof sheets combine aesthetic appeal with exceptional functionality. Their sleek design enhances any structure, while their lightweight nature ensures effortless handling and quick installation. Engineered for superior strength, these sheets excel under heavy weather loads and environmental stresses, making them a globally popular choice.

To meet growing market demands, we’ve developed a **high-speed Corrugated Sheets Rolling Forming Machine**, capable of producing **45 meters per minute** for efficient, large-scale production.

### **Key Advantages of Corrugated Steel Roofing:**

1. **Exceptional Durability** – Resistant to cracking, warping, and long-term wear.

2. **Pest & Rot Resistant** – Unlike wood, steel won’t decay or attract termites and wood-boring insects.

3. **Optimal Water Runoff** – Best installed on sloped roofs to ensure efficient drainage and moisture control.

4. **Anti-Corrosion & Algae Protection** – Chemically treated during manufacturing for extended lifespan.

5. **Fire & Heat Resistant** – Outperforms traditional materials like timber and asphalt in extreme conditions.

6. **Enhanced Signal Transmission** – Steel’s lightweight structure improves WiFi and mobile connectivity compared to denser building materials.

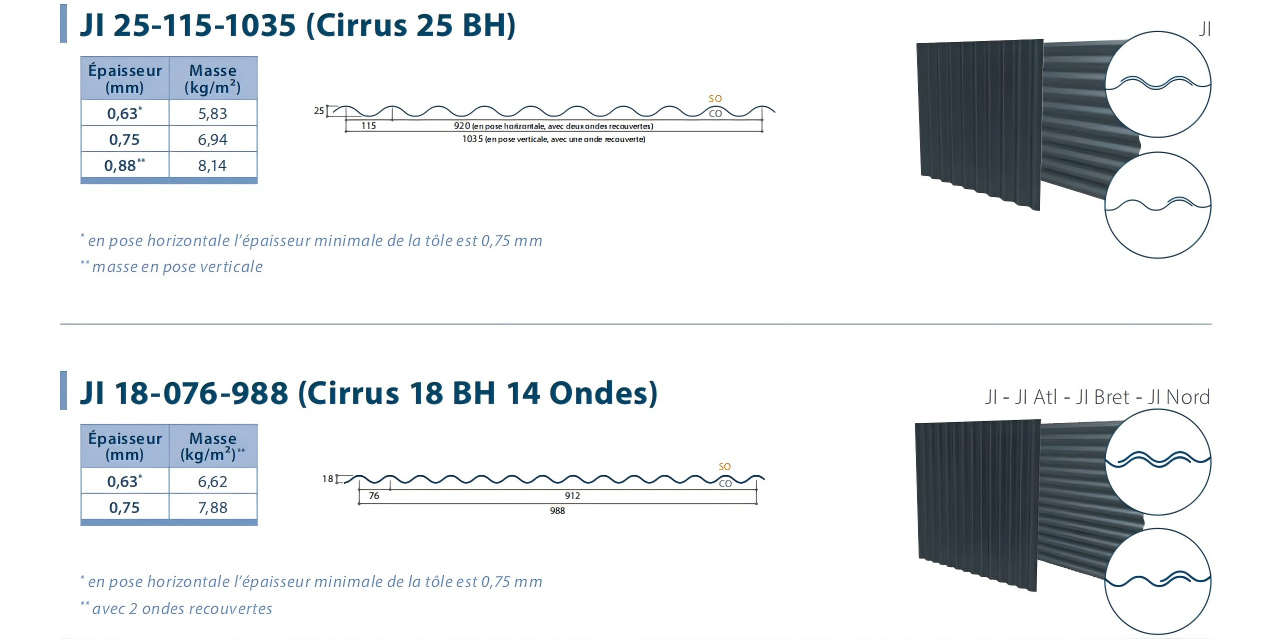

### **Popular Corrugated Roofing Profiles:**

Below are some widely used corrugated sheet profiles for your reference: *(Insert profiles here if applicable.)*

This version improves clarity, flow, and professionalism while maintaining all key details. Let me know if you'd like any further refinements!

Metal Roof Corrugated Sheets Rolling Forming Machine (45 meter per minute type)

|

Feeding device |

the platform width is adjustable by hand wheel, have bearing inside to protect edge of steel sheet. |

|

Rolling shaft |

Shaft Material: 40 Cr STEEL |

|

Shaft diameter: 80 mm |

|

|

Tempering treatment, prevent deformed and improve the hardness |

|

|

Roller |

Roller material: High grade 45# steel |

|

Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life |

|

|

Rolling station |

Rolling number: 22 stations for profile (separated mold rolling) |

|

Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. |

|

|

Work speed |

0-40 m/min |

|

Machine structure |

Iron casting Vertical arch frame structure |

|

Machine basic frame |

Hot rolled H-beam |

|

We will make diagonal bracing inside the frame, to strength the structure and keep the whole plate in same horizontal plane |

|

|

After the whole welding, vibration is used to weld the stress. After large-scale planer machining, the horizontal and rigidity of the frame are ensured. |

|

|

Bearing |

Chinese famous brand Harbin |

|

Work power |

7.5kw two motors so total power 15kw |

|

Roller treatment |

Electroplate (chromed) |

|

Safety cover |

1 set |

|

Transmission |

Gear box transmission(bevel gear inside) |

|

Advantage: can improve the speed directly after cutting |

The reason of why it can make thickness from 0.18 to 0.45mm thin Corrugated Sheets without damaging the surface of the coil:

Metal Roof Corrugated Sheets Rolling Forming Machine Working Video For your reference:

<iframe width="650" height="450" src="https://www.youtube.com/embed/zAJBEoHbahs?si=ak0q3s4U7Ax5YSqi" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" referrerpolicy="strict-origin-when-cross-origin" allowfullscreen></iframe>