Toggle Navigation

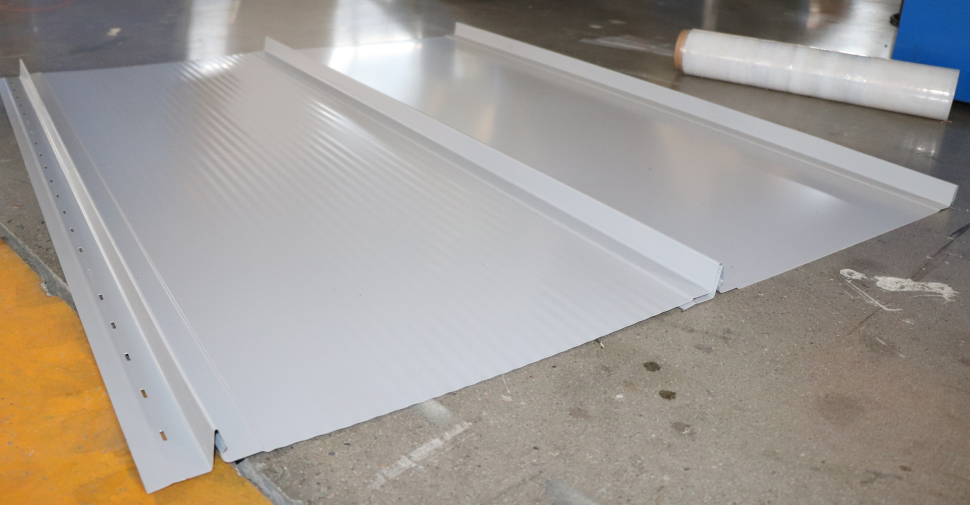

Snap Lock Standing Seam Roofing Panel Rolling Forming Machine

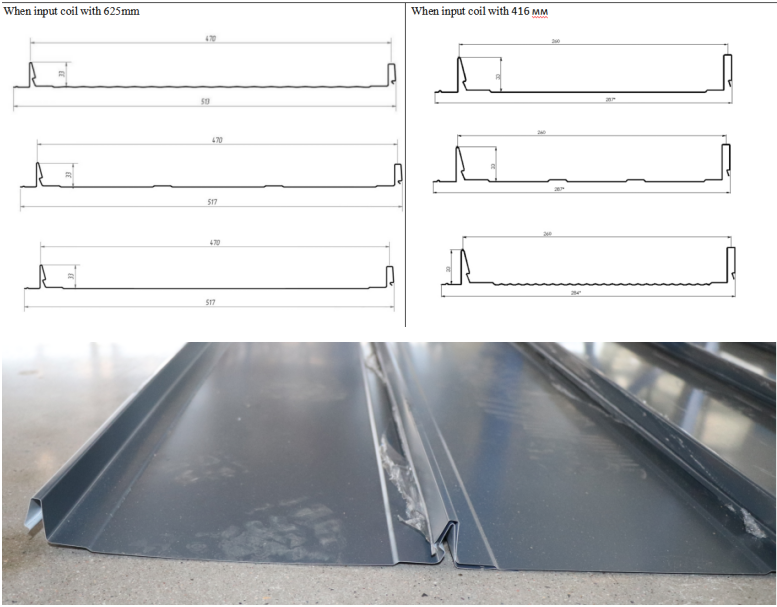

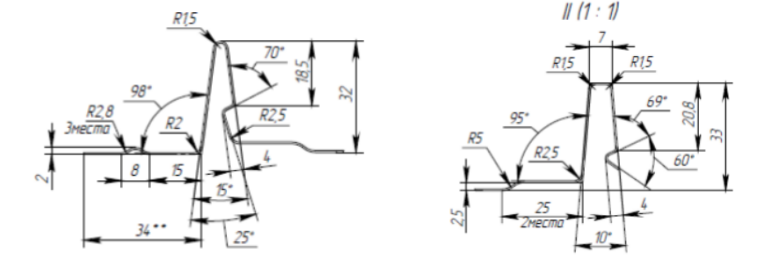

There are many different profile options for the roofing panels— including mechanical seam, snap-lock, and nail strip/fastener flange — are distinctly different in terms of performance, engineering and testing, slope requirements, attachment method, price, and so on. Here we will introduce one type width adjustable standing seam profiles, snap lock type here, also the metal embossing type also adjustable. Here are some drawing profiles for your reference:

There are two types width adjustable: when you use narrow strip or wide coil, you can choose the width range according to your requirements: As to the bottom ribs embossing pattern, we can design according to your requirements.

|

Here are some parameters for your reference: |

|

|

Feeding device |

One set guiding roller |

|

Steel plate welded platform to carry the sheet and feed into roll forming system |

|

|

Feeding width is adjustable with the handle wheels |

|

|

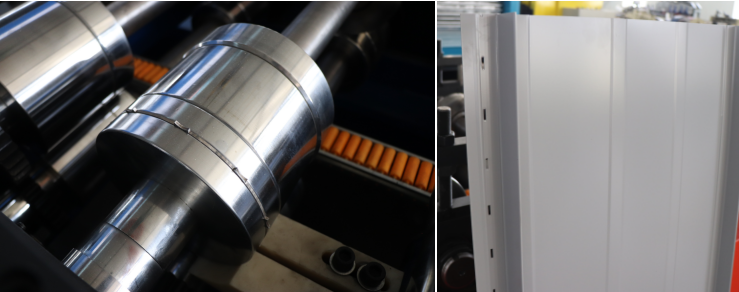

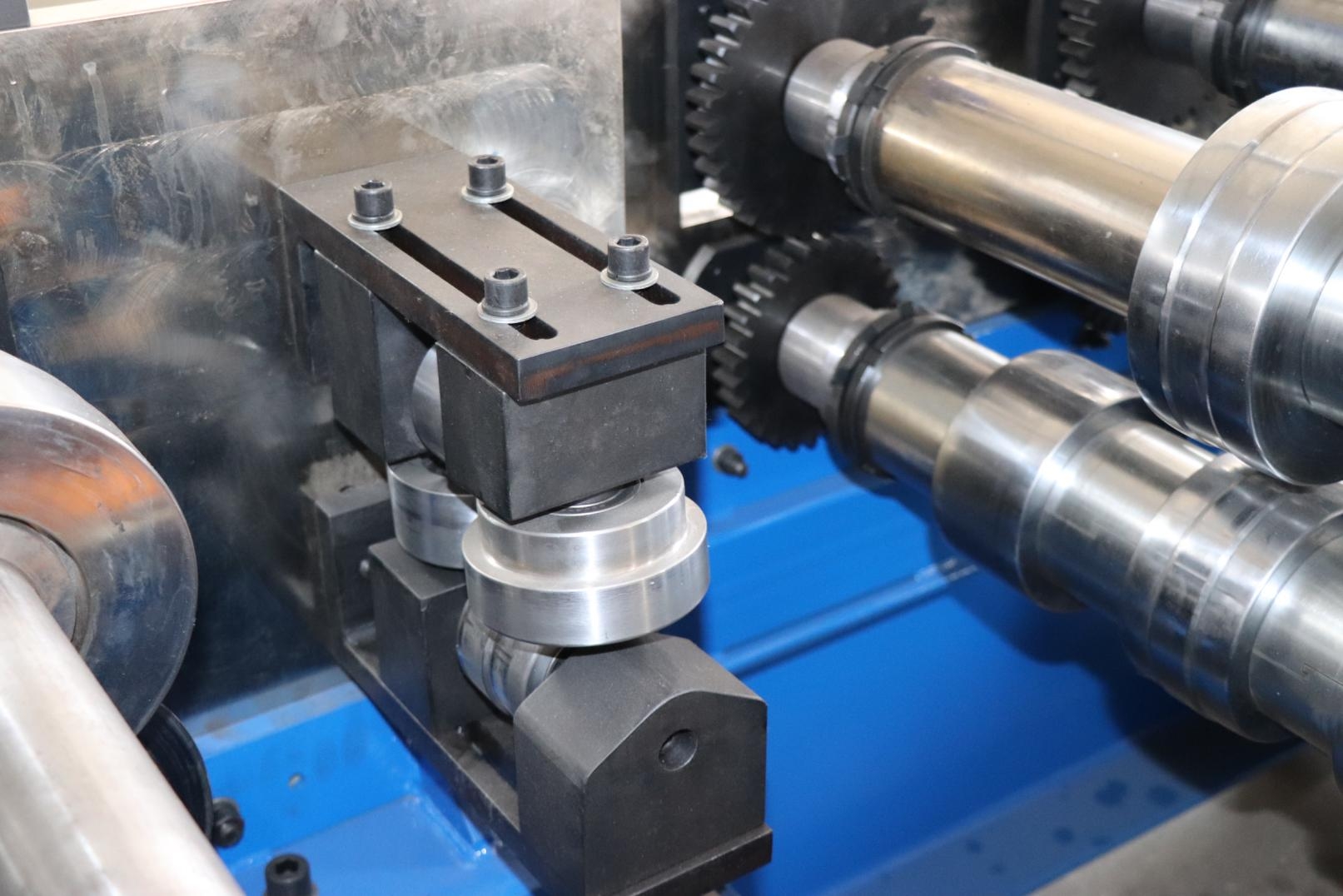

Rolling shaft Roller |

Shaft material:45# STEEL |

|

Shaft diameter: 75 mm |

|

|

Tempering treatment to prevent deformed and improve hardness |

|

|

45# steel |

|

|

Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life |

|

|

Rolling station |

21 roller station |

|

Work speed |

20 m/min |

|

Machine structure |

Steel plate welded structure |

|

Machine basic frame |

500# H steel welded |

|

Work power |

Main motor: 5.5 kw |

|

Rolling spacer |

Anti rusty treatment |

|

Pull rod |

Anti rusty treatment |

|

Transmission |

By Chains with cover |

|

Noted: please fill the lube in case the chains getting dry |

|

Features of Snap Lock Standing Seam Roofing Panel Rolling Forming Machine

5.Smap lock could be tightly.

We also have fixed type like width is fixed and then machine cost will be much more lower than this type. If you need to know more information, please contact us at any time.