Introduction

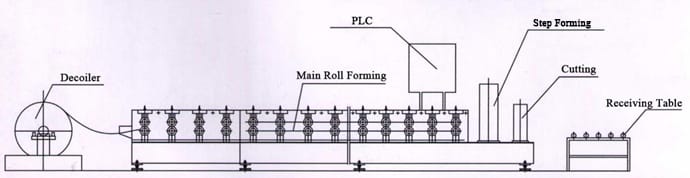

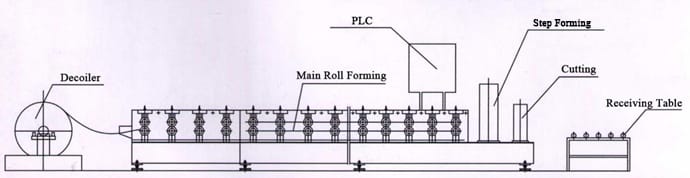

This 840 Glazed Tile Roofing HS Machine is customizable to manufacture 840 glazed tile roofings. This machine is specified to run in High Speed. Our machine is equip with removable switch, air break, radiator, transformer and electric leakage protector for operation convenience and safety. This machine is control by the PLC system with world famous brand such as Mitsubishi Electric, Siemens, Delta to ensure flawless production with precision for a lifetime. It is ideal for manufacturing 840 glazed tiles on demand with precision and speed.

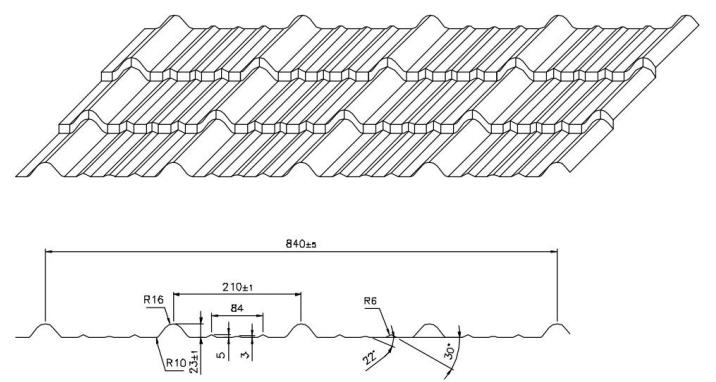

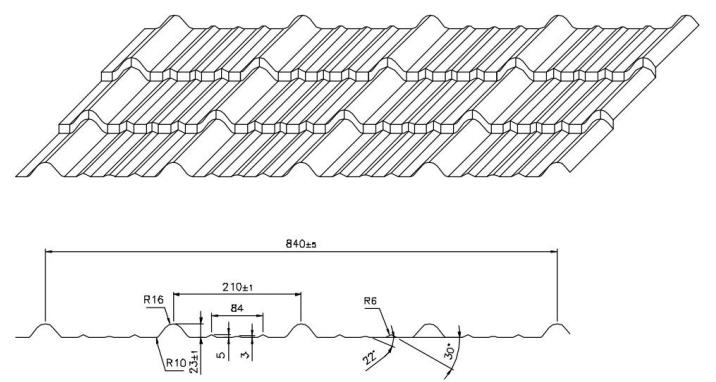

Profile Drawing

Machine Parameters

Machine Parameters

|

Roller stations |

13 roller station |

|

Roller material |

Gcr 15 steel after quenching processing HRC58-62℃, chrome plated surface |

|

Shaft material |

45# solid steel |

|

Shaft diameter |

φ 75mm |

|

Rolling speed |

25m/min |

|

Working speed (with stepping) |

7-8m/min |

|

Hydraulic cutting blade |

Gcr 12 Mov Chromed and quenched HRC 58-62 |

|

Hydraulic Cutting Power |

15kw with accumulator |

|

Hydraulic Oil |

46# |

|

Transmission |

Gearbox |

|

Electricity |

380V, 50HZ, 3 Phrase (Customizable) |

|

Forming motor power |

7.5kw Servo motor |

|

Main structure |

Middle plate welded |

|

Machine base frame |

500# H steel welded |

|

Color |

Blue & Yellow (Customizable) |

Machine Photos

High Quality glazed roof tile roll forming machine-Machine price The roof tiles made by our glazed roof tile making machine are in different colors and have beautiful appearance. These finished products are widely used in gardens, factories, resorts, hotels, exhibition halls and modern villas. ZhongTuo company can also design and manufacture other kinds of glazed roof tile making machines, such as 1100 tile water ripper glazed tile steel making roll forming machine, which is popular in Europe. If you want differnt sizes of glazed roof tiles, we can also design the accordingly machine for you to meet your needs. So cantact us and tell us what you require, we promise that you will be fully satisfied with our machines. Features: 1. Adopted PLC , transducer, touch panel to ensure high speed with stability, precision and lifetime. 2. Language: English and Chinese 3. Automatic length measurement 4. Automatic quantity measurement 5. Length Tolerance: 3m±1.5mm 6. Length inaccuracy can be amended easily. 7. Unit of length: millimeter (switched on the control panel) 8. Computer operating panel: touching screen and buttons. we are the professional manufacturer for roll forming machine in China and we export roll forming machinery all over the world.

please contact us, WhatsApp:+86 15613740026 Email:cnzt007@zhongtuocn.com www.cold-rollformingmachinery.com/,https://www.metalroofcomponent.com/

High Quality glazed roof tile roll forming machine-Machine price The roof tiles made by our glazed roof tile making machine are in different colors and have beautiful appearance. These finished products are widely used in gardens, factories, resorts, hotels, exhibition halls and modern villas. ZhongTuo company can also design and manufacture other kinds of glazed roof tile making machines, such as 1100 tile water ripper glazed tile steel making roll forming machine, which is popular in Europe. If you want differnt sizes of glazed roof tiles, we can also design the accordingly machine for you to meet your needs. So cantact us and tell us what you require, we promise that you will be fully satisfied with our machines. Features: 1. Adopted PLC , transducer, touch panel to ensure high speed with stability, precision and lifetime. 2. Language: English and Chinese 3. Automatic length measurement 4. Automatic quantity measurement 5. Length Tolerance: 3m±1.5mm 6. Length inaccuracy can be amended easily. 7. Unit of length: millimeter (switched on the control panel) 8. Computer operating panel: touching screen and buttons. we are the professional manufacturer for roll forming machine in China and we export roll forming machinery all over the world.

please contact us, WhatsApp:+86 15613740026 Email:cnzt007@zhongtuocn.com www.cold-rollformingmachinery.com/,https://www.metalroofcomponent.com/