Introduction

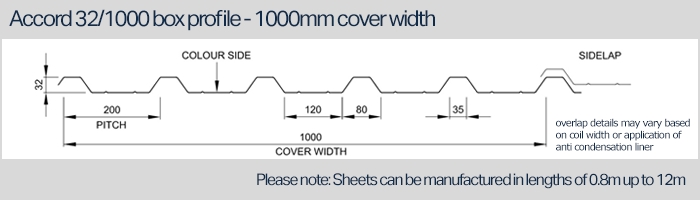

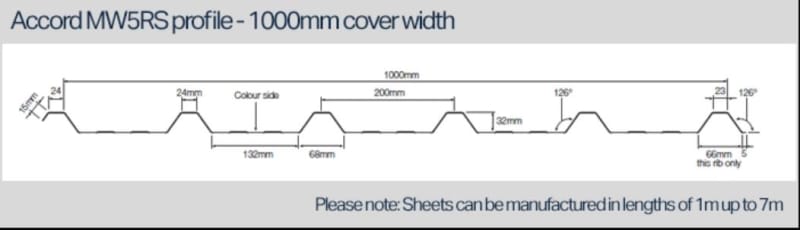

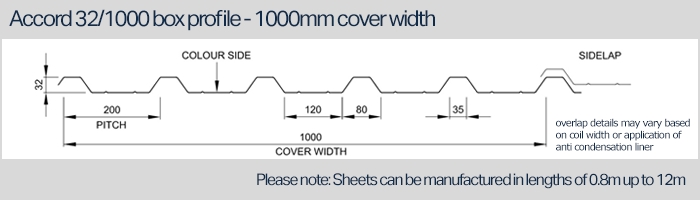

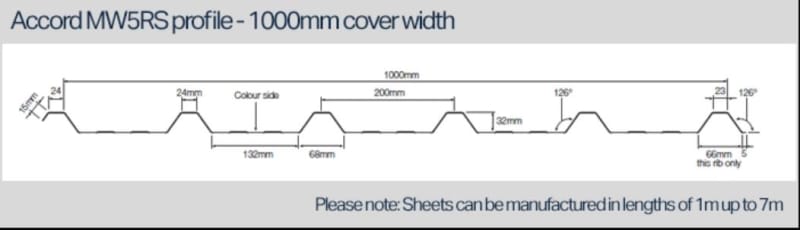

Double layer roofing sheet machine for Europe is designed to make the metal roofing sheets for Europe in batch fully automatically. Here I will take some popular design for UK for example: Box profile steel cladding (aka box section or trapezoidal cladding) is a modern alternative to traditional 3" corrugated (or wriggly tin) metal roofing sheets. Giving a more modern appearance it is becoming favoured with domestic properties and has a more industrial appearance for industrial buildings.

Profile Drawing

Technicial Parameters (Depend on customers specification)

Technicial Parameters (Depend on customers specification)

|

Roller stations |

Upper layer: 18 roller station

Lower layer: 18 roller station |

|

Roller material |

Gcr 15 steel after quenching processing HRC58-62℃, chrome plated surface |

|

Shaft material |

45# solid steel |

|

Shaft diameter |

φ70mm |

|

Working speed |

Upper layer: 0-12m/min

Lower layer: 0-12m/min |

|

Hydraulic cutting blade |

Gcr 12 Mov Chromed and quenched HRC 58-62 |

|

Hydraulic Cutting Power |

4kw |

|

Hydraulic Oil |

46# |

|

Transmission |

Chain with protective cover |

|

Electricity |

380V, 50HZ, 3 Phrase (Customizable) |

|

Forming motor power |

5.5kw |

|

Main structure |

Middle plate welded |

|

Machine base frame |

500# H steel welded |

|

Color |

Blue & Yellow (Customizable) |

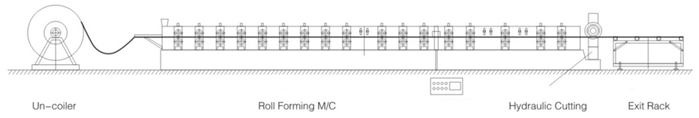

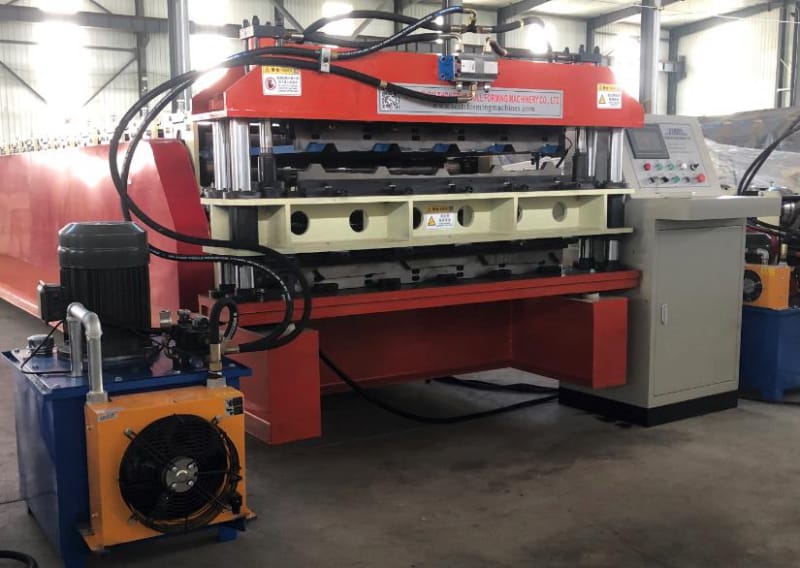

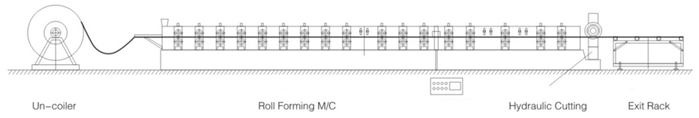

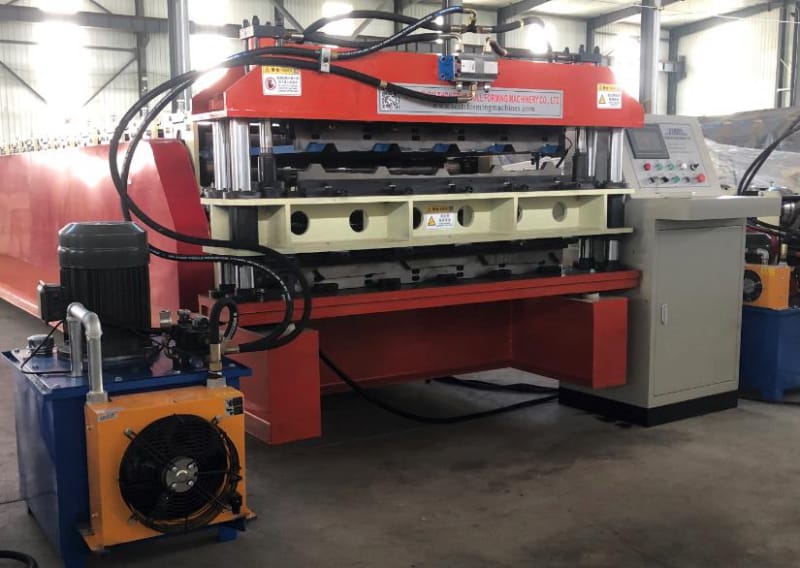

Machine Sample Pictures

Roll forming is continuous bending operation in which a long strip of metal sheet (usually steel coils, like PPGI, PPGL, GI, PPGL, BGL, Aluminum etc.) passes through sets of rolls mounted on consecutives stand each set performing only an incremental part of the bend, until the desired cross-section profile is obtained. Roofing sheet roll forming machine consists of an automatic Decoiler feeding guide, roll forming unit, hydraulic cutter with PLC base control system. We are involved in offering a wide array of color sheet making machine that is manufactured using high grade raw material and the latest technology with the set universal standards. These products are available in various specifications and can be customized as per variegated demands of our prestigious clients. Highest output speeds up you 30-40 meters per minute results in at least 10-15 times higher production. Maximum utilization of your investment practically any shape can be formed with uniform cross sections. Any complicated Shape Profile can be formed on our roll forming. Accuracy and consistency in Shape & dimension can be achieved. Reduced delivery period to meet your production needs quickly. We develop Roll Forming Line & Roll Tooling on our most modern software up grated with our enriched experience and technology. We have in-house CNC & VMC machining centers to produce roll tools with our own quality control and check.

Sheet Roll Forming Machines at Best Quality 1. Metal Rolling Shutter door manufacturing machine. 2. Metal door frame rollforming machine. 3. Metal Window Frame roll forming machine. 4. Automatic Slotted angle roll forming machine 5. False Ceiling profiles roll forming machine 6. Roofing Sheet Roll forming machines 7. Fully automatic C & Z Purline Roll forming lines with Online Punching system. 8. Fully Automatic Solar Structure profiles Roll forming and punching lines. 8. shutter roll forming machine 9. rolling shutter machine All types of Roll Forming, sheet metal processing, and fabrication machinery.

Roll forming is continuous bending operation in which a long strip of metal sheet (usually steel coils, like PPGI, PPGL, GI, PPGL, BGL, Aluminum etc.) passes through sets of rolls mounted on consecutives stand each set performing only an incremental part of the bend, until the desired cross-section profile is obtained. Roofing sheet roll forming machine consists of an automatic Decoiler feeding guide, roll forming unit, hydraulic cutter with PLC base control system. We are involved in offering a wide array of color sheet making machine that is manufactured using high grade raw material and the latest technology with the set universal standards. These products are available in various specifications and can be customized as per variegated demands of our prestigious clients. Highest output speeds up you 30-40 meters per minute results in at least 10-15 times higher production. Maximum utilization of your investment practically any shape can be formed with uniform cross sections. Any complicated Shape Profile can be formed on our roll forming. Accuracy and consistency in Shape & dimension can be achieved. Reduced delivery period to meet your production needs quickly. We develop Roll Forming Line & Roll Tooling on our most modern software up grated with our enriched experience and technology. We have in-house CNC & VMC machining centers to produce roll tools with our own quality control and check.

Sheet Roll Forming Machines at Best Quality 1. Metal Rolling Shutter door manufacturing machine. 2. Metal door frame rollforming machine. 3. Metal Window Frame roll forming machine. 4. Automatic Slotted angle roll forming machine 5. False Ceiling profiles roll forming machine 6. Roofing Sheet Roll forming machines 7. Fully automatic C & Z Purline Roll forming lines with Online Punching system. 8. Fully Automatic Solar Structure profiles Roll forming and punching lines. 8. shutter roll forming machine 9. rolling shutter machine All types of Roll Forming, sheet metal processing, and fabrication machinery.

Mr.Jimbo-ZTRFM

Cangzhou Zhongtuo Roll forming Machine Co.,Ltd

Add: Industrial Zone,Botou,Cangzhou,Hebei,China.

Email:

cnzt007@zhongtuocn.com

Whatsapp wechat Phone:+8615613740026

https://www.metalroofcomponent.com/