Toggle Navigation

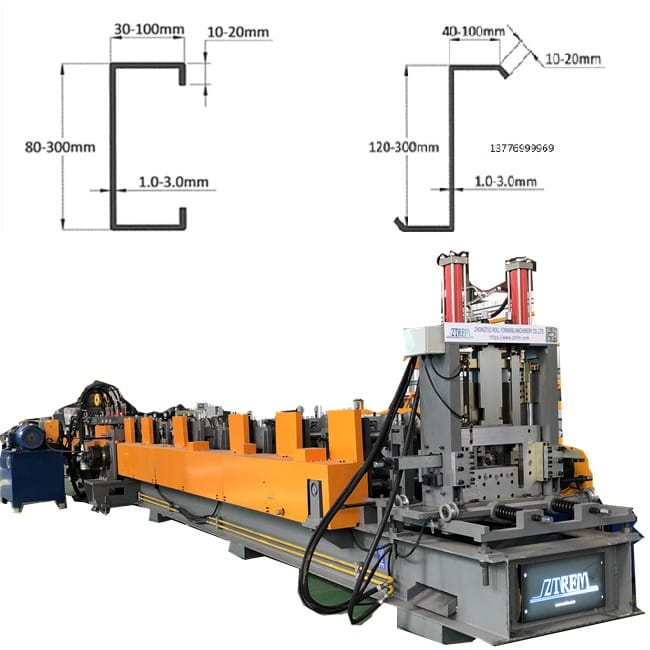

Galvanized Cee Purlins Zee purline rolling forming machine is designed to make C purline, Z purline in batch fully automatically with punching or without.

Cee Purlins For Metal Roofing

Designed to reduce the distance the rafters have to span, metal purlins support the loads from the roof deck and help to prevent the roof from sagging.

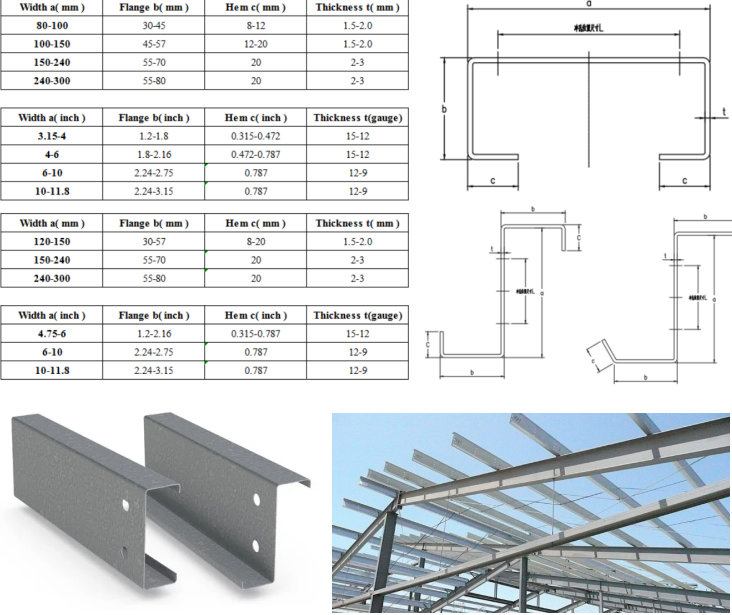

C Purlin - Cee or C purlins are shaped like a squared-off letter C. They are often used for structural support in walls and as floor joists in addition to roofs.

Z Purlin - The zee or Z purlin is shaped like a letter Z. Its shape allows the purlin to overlap with others at the joints. This gives zed purlins the potential to be much stronger than C purlins. Z Purlins are mainly used in walls or for large roofing projects. Here are some drawing profiles for your reference:

Galvanized Cee Purlins Zee purline rolling forming machine

Configuration requirements :

Manual recveive table

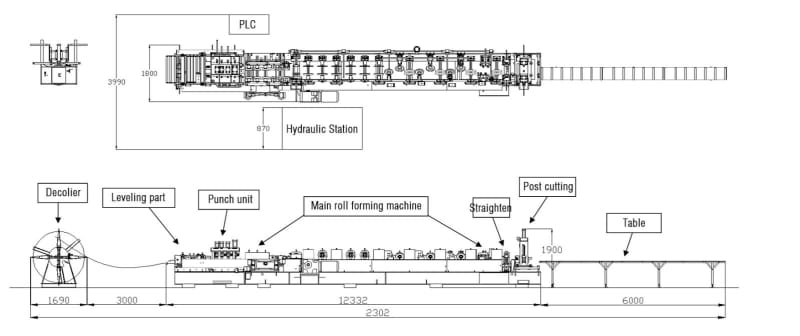

Galvanized Cee Purlins Zee purline rolling forming machine working flow:

Galvanized Cee Purlins Zee purline rolling forming machine More in details:

Automatic decoiler or manual one: Capacity:6 tons

Feeding and leveling part

There is an electric button here, which can automatically adjust the feeding width

Leveling rollers: 3 up 4 down

Roller material: Cr15

Roller diameter: 75mm

Feeding width adjustment: automatic by button

Make sure inputted steel sheet straight and neat and then roll forming process could be made accurate

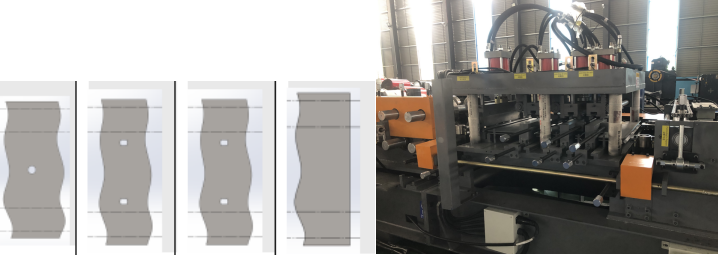

Punching and pre shearing part

Punching unit with hydraulic system;

Punching mold:Gcr12 quenched treatment

Station 1: Bottom double side holes punching

Station 2: Bottom double side holes punching

Station 3: Pre-Hydraulic shearing

Main rolling forming machine of CZ purline machine:

Roller material:

Cr12 CNC processing heat treatment to HRC: 58-60 ,finish turning

Roller stations :21 rows

Diameter of shafts:Φ80 mm solid

Material of shafts:

40 Cr CNC processing HRC28-32 ,finish turning and electroplate

Forming speed: max 15m/min

Voltage: 480V/60HZ/3P (as requested)

Transmission way :

Double chains + shaft end support

Servo motor power: 60 Kw

Sizes changing: Automatically by PLC

C and Z purling change : By Automatic or Manual

Hydraulic cutting system

Material of blade: Cr12mov quench treatment

Length measuring: automatic encoder measuring, tolerance of length is 1mm/3m

You can manually adjust the cutter to cut different sizes of c/z purlin. You do not need to change new blade and this cutter is easy to operate.

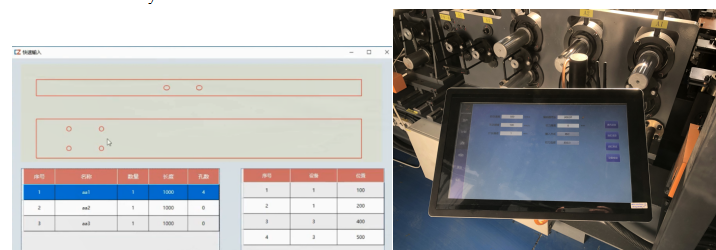

PLC Control system

1 set computer control + intelligent control system + production rapid input software:

U disk can quickly import production data .

Remote transmission Genuine WINDOWS system laptop.

Production visibility:

Automatic stacker:

Length: 6 meters

The frame body is welded with channel steel and angle steel, and the roller is installed on the surface

Related suggestion:

If the local labor cost is high, you can also choose automatic palatalizing ( Price:28000 USD )

Galvanized Cee Purlins Zee purline rolling forming machine working video for your reference:

<iframe width="650" height="450" src="https://www.youtube.com/embed/i0q7YU1Vdwg?rel=0" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" allowfullscreen></iframe>