Toggle Navigation

Pallet Rack Step Beams /L Tube Step Beam rolling forming machine

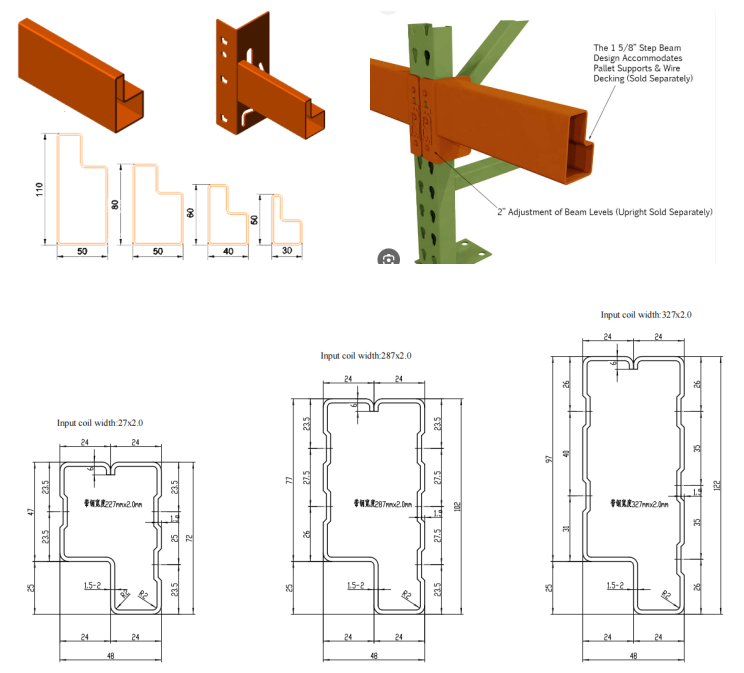

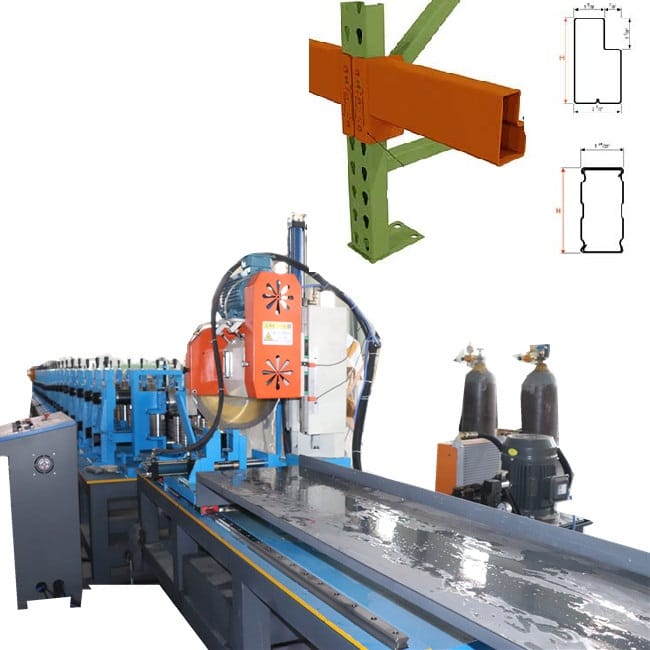

Pallet Rack Step Beams /L Tube Step Beam rolling forming machine is designed to make the step beam in batch fully automatically.Common features include of Pallet Rack Step Beams /L Tube Step Beam:

Roll-formed steel construction with a continuous seam weld located on the base for exceptional stability and strength

Integrated safety locking pins located on both ends to hold beams securely in place

Lifting capacities between 4,046 lbs. and 9,370 lbs.

A powder-coated, baked-on orange finish that provides both corrosion resistance and visibility

Spot welding type that can be counted on for years of heavy, industrial use.

And the step beams are an integral part of pallet racking systems in warehouses, distribution centers, manufacturing facilities, big-box retail stores and more.

In the market, step beam has two types: interlocked type(the material thickness can not beyond 2.0mm) and the welding types(the thickness can reach 3.0mm ). Here we take some drawing profile for your reference:

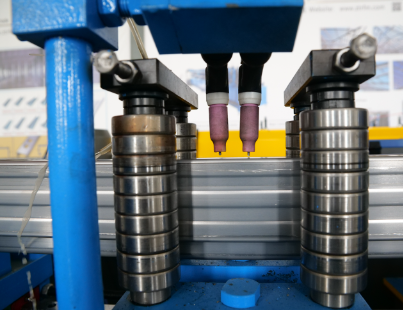

For the P beam or step beam design, we can make according to your requirements like adding ribs, spot welding or seam whole line welding. You can choose TIG welding or Laser welding or high frequency welding. The welding tool will effect the step beam welding effect and speed. Here are some P beam made by our machines for your reference:

Pallet Rack Step Beams /L Tube Step Beam rolling forming machine

|

||||||||||||||||||||||||||||||||||||||||

|

The work flow for P beam rolling Machine |

||||||||||||||||||||||||||||||||||||||||

|

Decoiler- feeding- leveling - roll forming- - welding- cutting- receiving table.

|

||||||||||||||||||||||||||||||||||||||||

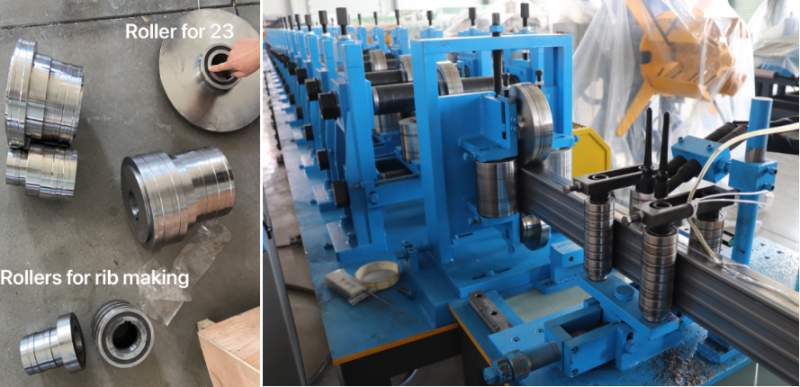

Main Rolling of Step Beam Forming Machine

Machine base frame is made of U beam weld steel. In the main roll forming machine, there are 2 buttons for urgency stop in case any accident happens. Machine stations are made of iron cast to make machine stable and strong. Main motor power (electric motor): 18.5 kw

Table frame: 460 U beam

Main roll forming

Roller station: 28 stations system

Roller material: Cr15 quench treatment precision machining, hard chrome-plated ,HRC55-60

Shaft diameter:¢80mm

Shaft material: S45C, heat treatment HRC42

Pinching device: 2 Steps of pinching

Transmission: by chain

Roller stand: cast steel structure

Width adjust motors (electric motor): 1.5 kw*1 set, 0.75*2 sets

Voltage: 480V 60HZ 3Ph

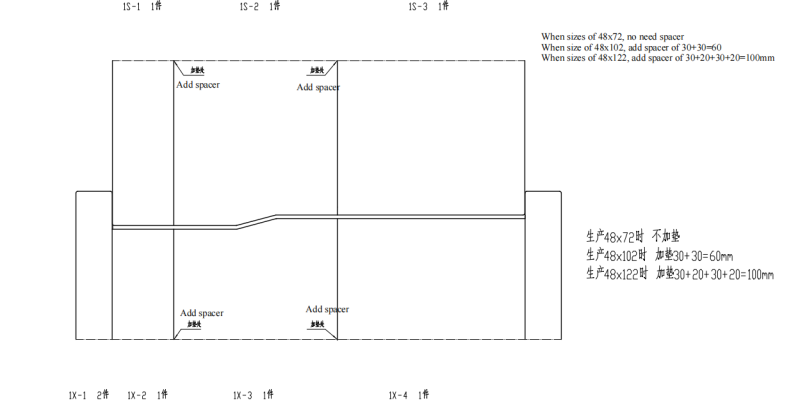

As to how to change the sizes from one to another, we will give the following drawing like this:

Simple change the rollers and adjusting the spacer according to the drawing profile. If you want to make the automatic type, we can also make for you.

More advantages of Pallet Rack Step Beams /L Tube Step Beam rolling forming machine

As leader roll forming machine manufacturer in china, Tecform is capable to design and manufacture top quality custom roll forming machines and professional service with global footprint. Roll Forming Machines: Metal roof & wall panel roll forming machine, Steel tile roll forming machine, Dual Level roll forming machine, C/Z/U/Sigma purlin roll forming machines, Drywall stud and track roll forming machine, Steel floor deck roll forming machine, Highway guardrail roll forming machine, Downspout roll forming machine, Gutter roll forming machine, Portable downspout / gutter machines, Door frame roll forming machine, Roller shutter roll forming machine, K span arched roof roll forming machine, Furring channel roll forming machine, Sigma post roll forming machine, Storage rack / shelf roll forming machine, Curtain rail roll forming machine, Roof ridge cap roll forming machine, IBR sheet roll forming machine, Corrugated sheet roll forming machine, Trapezoidal sheet roll forming machine, Cable tray roll forming machine, Door track roll forming machine, etc Cell/WhatsApp: +86-115613740026 cnzt007@zhongtuocn.com

Pallet Rack Step Beams /L Tube Step Beam where to use:

Pallet Rack Step Beams /L Tube Step Beam rolling forming machine working videos for your reference:

<iframe width="650" height="450" src="https://www.youtube.com/embed/3UEsxKEC8EQ?rel=0" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" allowfullscreen></iframe>