Toggle Navigation

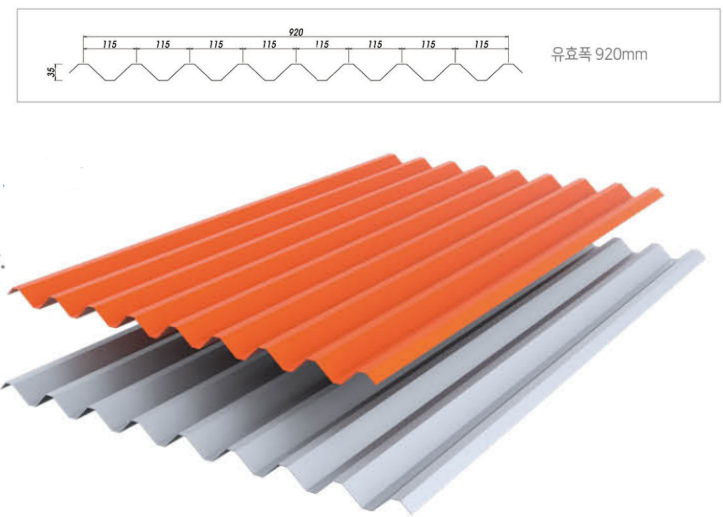

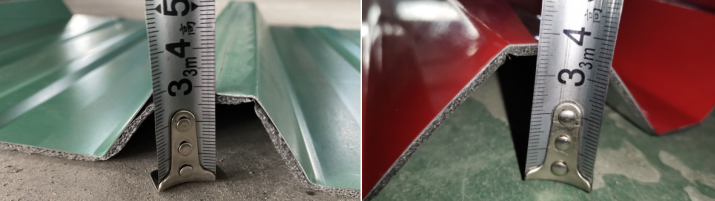

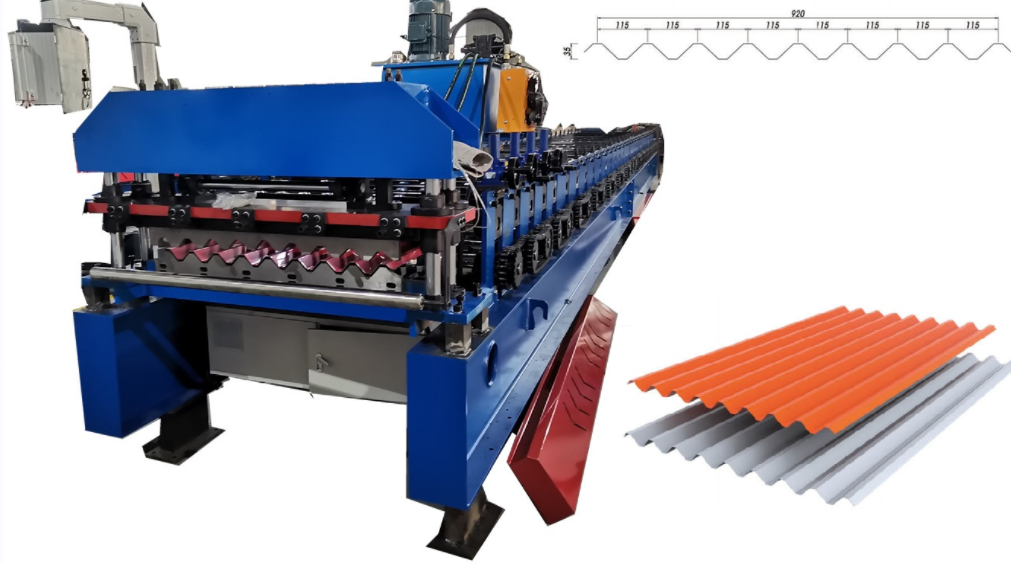

Stainless steel filmed PPGI metal roofing sheet rolling forming machine is designed to make the high strength coil sheet rolling forming machine. Stainless steel roof tile rolling machine is a equipment used for producing stainless steel roof tiles. Stainless steel roof tiles are a high-strength, corrosion-resistant, and weather resistant roof covering material commonly used in industrial buildings, commercial buildings, and residential areas. Stainless steel roof tile equipment usually consists of a rolling machine, forming machine, cutting machine, etc. By processing and forming stainless steel sheets, it produces stainless steel roof tile products that meet the requirements. These devices can automate the decoiling, forming, cutting and other processes of raw materials, improve production efficiency, and ensure product quality. Meanwhile such machine also can be used to make normal PPGI and filmed PPGI coil. Here we will take the normal V115 profile for example to show the detail parameters of machine.

Stainless steel filmed PPGI metal roofing sheet rolling forming machine:

Features of Stainless steel filmed PPGI metal roofing sheet rolling forming machine:

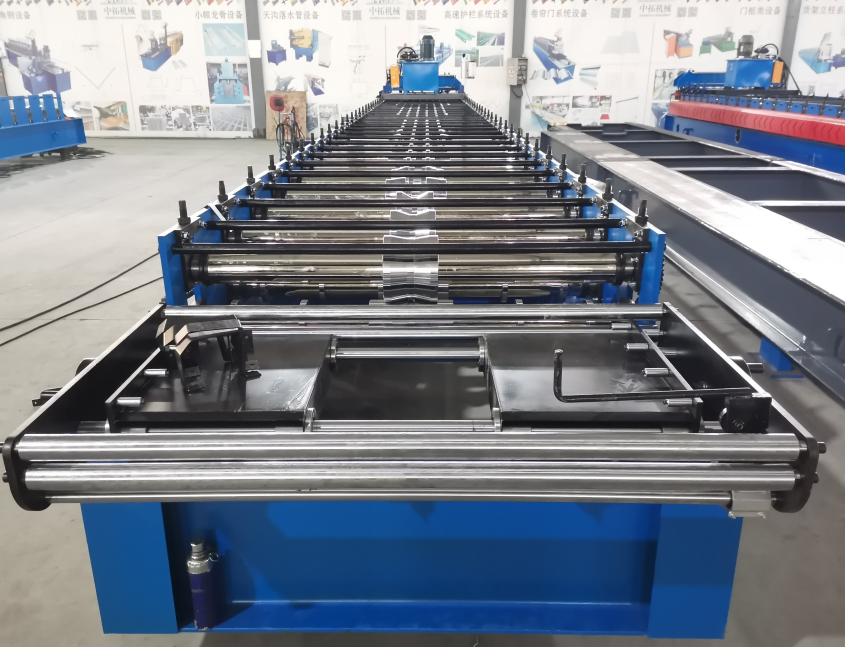

For the shearing part, we use the strong 4 pillar pole supporter and cutter holder with embedded cutting blades, by this way, the cutter will be more durable and more powerful.

<iframe width="560" height="315" src="https://www.youtube.com/embed/1hVUxUSRJ3c?si=aCIzByrCn5U6IaT4?rel=0" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" allowfullscreen></iframe>