Composite metal floor decking rolling forming machine

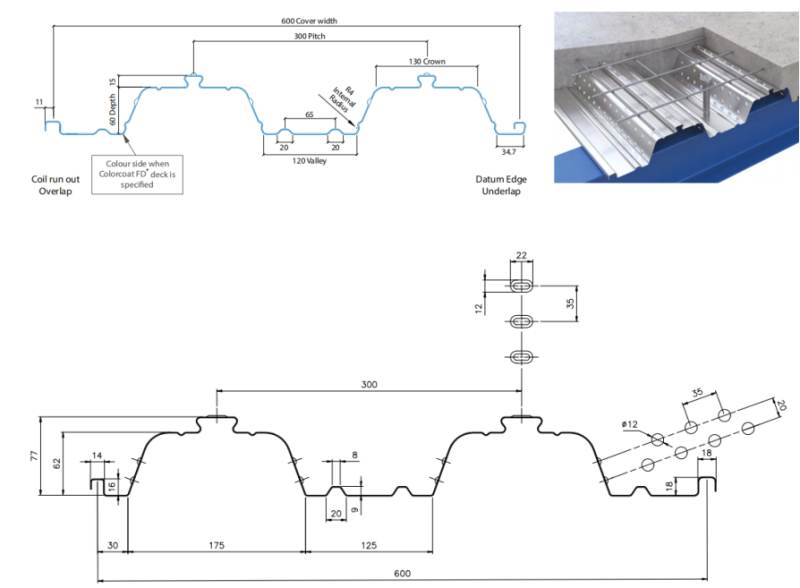

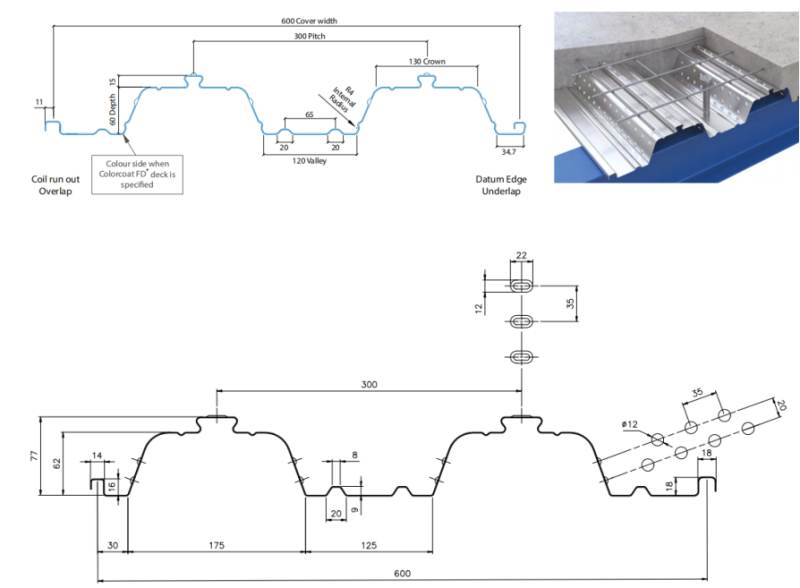

Composite metal floor decking rolling forming machine is designed to make the metal decking sheet in batch fully automatically . Combined trapezoidal and re- entrant 80mm composite profile with long span capability. Versatile. Combined profile allows easy service attachment, with trapezoidal spanning ability. Here will show you some popular designs for your reference:

They are different in the height and embossing types, so those data could be customized according to the input coil width and customer requirements. Here are some decking pictures with single profile and overlapping for your reference:

-

Metal decking is a versatile building material that can be used for a variety of applications, including roofing, flooring, and walls. It is strong, durable, and fire-resistant.

-

Roll forming machines are used to create a wide variety of products, including metal decking, gutters, and channels. They are a versatile and efficient manufacturing process.

-

Steel decking floor forming machines are a type of roll forming machine that is specifically designed to create metal decking for floors. They are typically used in commercial and industrial construction.

-

Zhongtuo Steel Decking Floor Roll Forming Machine is a specific brand of steel decking floor forming machine that is known for its quality and durability. It is manufactured by Zhongtuo Machinery, a leading manufacturer of metalworking machinery.Frame design: keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Length of the main part: about 25000 х1650 х1500

Weight of main part: 15300kg

Voltage : Customize

Roller fixer : middle plate of thickness 28mm

Frame : 400 H steel welded

Drive mode: double chain with the chain adjuster for lose and tight degree.

Material of rollers:Gcr15, surface hard chromium plating.

Material of shafts: 45# steel and adjusting the hardness.

Diameter of shafts: φ 90mm embossing rollers are about 120mm.

Number of rollers : 36 rollers

Main power: 15*2 kw

Shearing Mechanism

Feature : Ensure stability, precision and cutting speed

Function : Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: C r12 quenched

Power supply : hydraulic power

Components:It contains one set of blade , one hydraulic tank and one cutter machine.

You can choose to add the before shearing or not . If you wan to add, you can cut at any length and reduce the wastage of the coil in the machine.

-