Toggle Navigation

|

Main motor power |

15kw |

|

Voltage |

380v 50hz 3phrase |

|

Control system |

PLC |

|

Feeding thickness |

1.5mm |

|

Speed |

15-20m/min |

|

Roller station |

32 stations |

|

Shaft diameter |

90mm |

|

Shaft material |

45# steel |

|

Roller material |

45# steel |

|

Cutter material |

Cr12 Mov |

|

Base frame |

500# H steel welded |

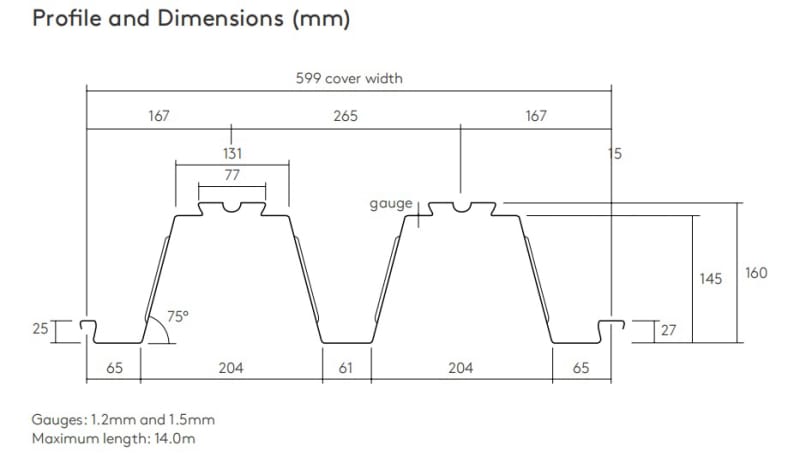

1. Zhongtuo metal decking machine can produce a variety of specifications of the floor bearing plate, can also be customized according to the customer's requests, to meet the needs of all customers.

2. Machine working speed can possess the production speed of up to 25 m/min.

3. Modular design and manufacturing. parts universal rate are high, simple maintenance.

4. The enhanced design of the mainframe structure and quality control allows our metal rolling equipment to produce thicker plates for you.

5. AII the processing of the frame is completed at one time, and the advanced machine tools ensure the accuracy of the size and position of each fit so that our molding unit almost does not need repeated debugging, with very little dependence on personnel.

6. The automatic program control technology is adopted. The parameter setting of the metal deck roll forming machine is simple and convenient, and the degree of automation is high. The system's self-learning ability is strong, and the control system uses the high-quality brand. In addition, the man-machine interaction interface is also very user-friendly.

7. For the special design of the shaft and embossing rollers, it can make sure the metal profile has good overlapping effect and good profile shape size.