Toggle Navigation

Brief Introduction

The Roof panel made by our Aluminum IBR Roof Sheet Steel Profile Roll Forming Machine Manufacturer have beautiful appearance and bright color, high strength .

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands,

ancient architectures and modern villas.

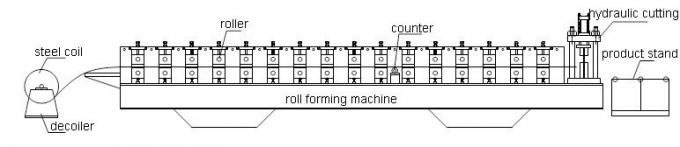

Working Flow of Aluminum IBR Roof Sheet Steel Profile Roll Forming Machine Manufacturer

echnical Detail

A Sheet Specifications

| 1 | Coil Type | PPGI GI |

| 2 | Width | 1250mm |

| 3 | Thickness | 0.3-0.8mm |

| 4 | Yield stress | Q235 |

| 5 | Effective | 900mm |

B Components Details

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate |

16mm. We use thicker plates to ensure stability

of our products. |

| Forming Steps | 15, according to the drawing. |

| Shaft Material | Φ70 mm, high grade 45# steel. |

|

Treating process: tempering- finish turning,

high rigidity, hard to deform. |

|

|

Cutting

Blade Material |

Cr12, hardness HRC60-62. |

| Treating process: heat treatment- plane abrasion- wire electrode cutting. |

C Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 7 inch touch screen, easy to operate. |

| PLC | Delta DVP 14ES |

|

well-adapted to various conditions, such as moisture,

electromagnetic disturbance. |

|

| Frequency Converter |

Delta VFD-M. It has the advantage of slowing down before cutting,

to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

|

Length

Measurement Device |

Omron, made in Japan. |

| It features with high accuracy and stability. |

More Pictures of Aluminum IBR Roof Sheet Steel Profile Roll Forming Machine Manufacturer