Toggle Navigation

Metal roofing tile glazed tile making machine aluminium step tile machine

What is the application of Metal roofing tile glazed tile making machine aluminium step tile machine? wall and roof panel roll forming machine is mainly product in large span factory building, warehouse, office buildings, villas, roof, cold storage, air purification room, stores, kiosks, and temporary housing.

What is the advantage of Metal roofing tile glazed tile making machine aluminium step tile machine

1.The system is easy to operate and use.

2.The surface of the final product is very smooth and beautiful without any scratch on the surface.

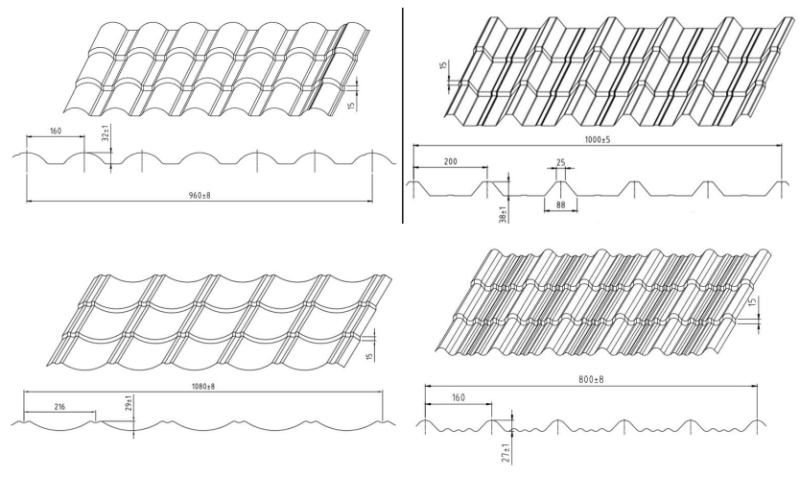

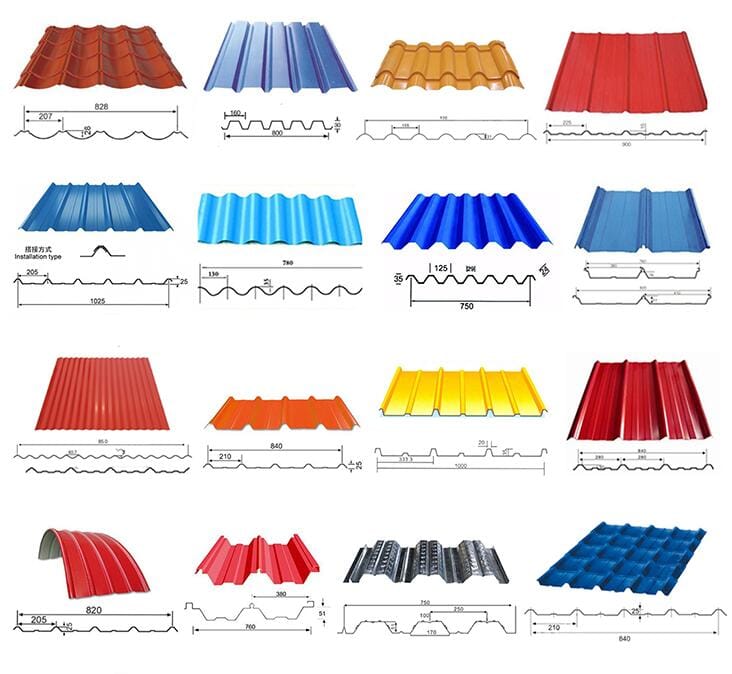

3.Customized:design the machine according to your specification and profile drawing.(for your reference)

| NO. | NAME | UNIT | QUANTITY |

| 1 | 5 tManual decoiler | set | 1 |

| 2 | Roll former | set | 1 |

| 3 | Control Cabinent | set | 1 |

| 4 | Hydraulic station | set | 1 |

| 5 | Put-out table | set | 1 |

| 6 | Spare parts | set |

1 |

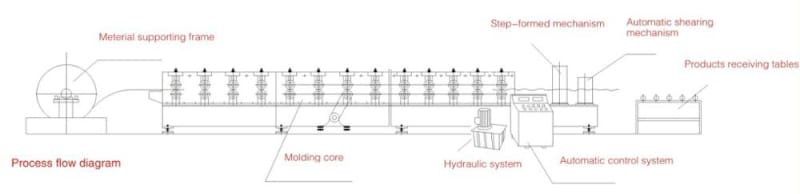

1.Manual decoiler (also can use hydraulic decoiler as customers' request)

Capacity:5T

Coil diameter:450-550mm

Coil outer diameter:1500mm

Coil width:1250mm(as customers' request)

2.Main roll forming machine

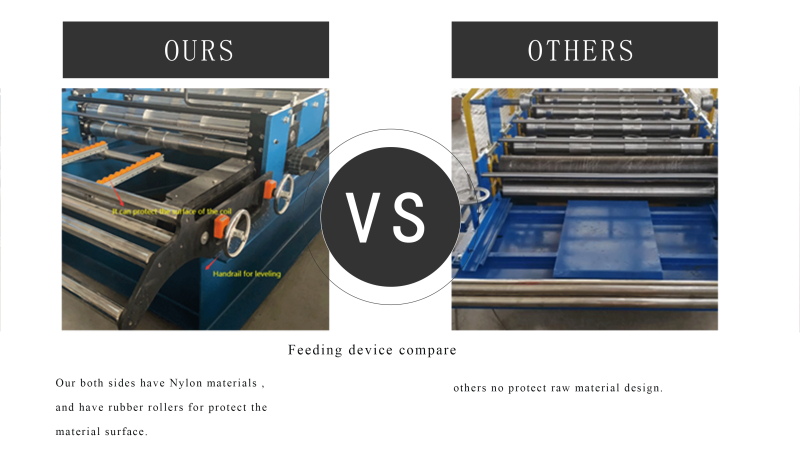

Feeding device:with two hand wheels to adjust the feeding of the material,with bearing inside of the feeding rollers.

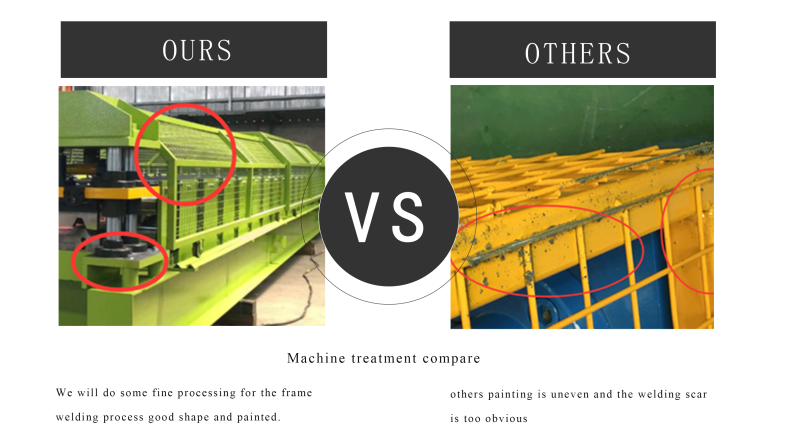

Frame:350H steel,with 20mm middle plate support

Roller stations:15 stations(depend on the profile drawing)

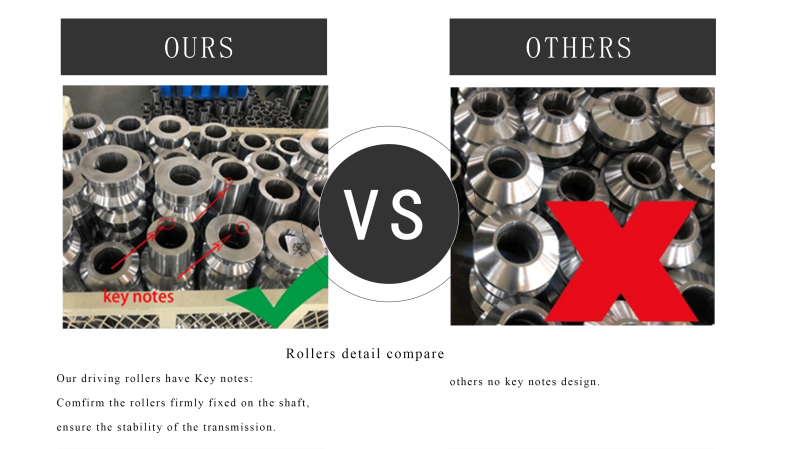

Roller materila:45# steel with quenched treatment and hard chroming

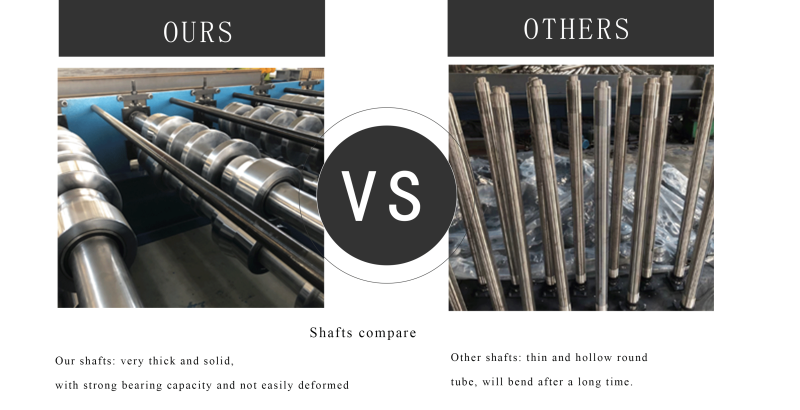

Shaft diameter:80mm,solid

Shaft material:45# steel with tempering treatment

Motor power:5.5kw

Speed:3-5m/min

Transmission:By double chain

Voltage:380V,50HZ,3P

3.Hydraulic cutting system

Blade material:Cr12,with quenched treatment

Hydraulic power:4kw

Cutting tolerance:±1mm

With fan cooling on the oil pump

4.Control system

Control system:PLC

PLC brand:Delta from Taiwan

Frequency converter brand:Delta from Taiwan

Encoder:Omron

Function:Automatic control the length and quantity

5.Product run out table

Type:manual(also can use the auto stacker as customers' request)

Length:3m

For more detailed and accurate technical datas of the machine,pls feel free to contact me.

WhatsApp:+86 15613740026 cnzt007@zhongtuocn.com

Machines are customized as your drawing,here hot sale drawing profiles for your reference.