Toggle Navigation

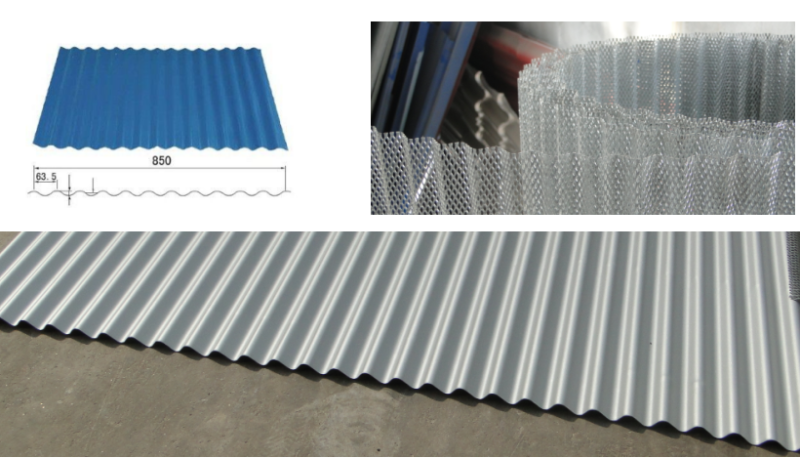

High speed corrugated roof sheet making machine can be used to make the metal roofing sheets in the speed of 45 meter per minute. When comes to corrugated roof sheet making machine, you may have the following questions or ideas?

6 Related elements of optional:

Hydraulic decoiler 5 ton, 7 ton or 10 ton.

Automatic stacker

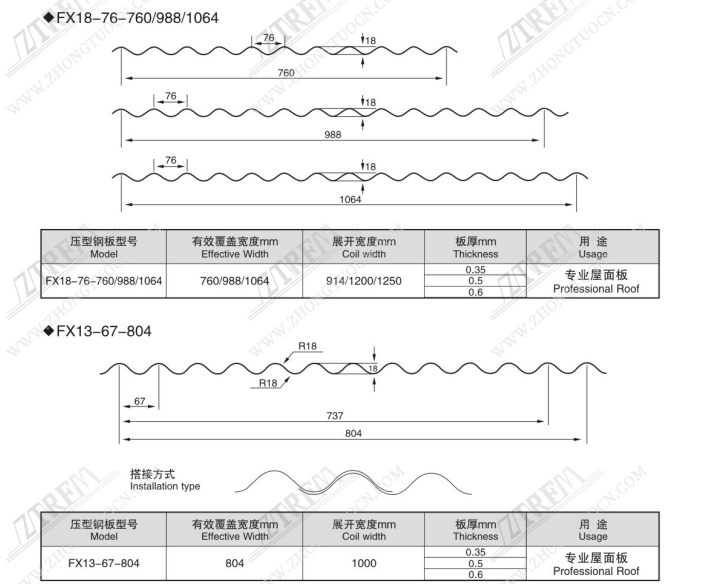

Here we take a random drawing profile to show you the high speed corrugated roof sheet making machine and others we will introduce one by one on our website.

High speed corrugated roof sheet making machine:

|

No. |

Name |

Unit |

Quantity |

Remark |

|

Part 1 |

7 T decoiler with loading car |

set |

1 |

Automatic |

|

Part 2 |

Main roll forming machine |

set |

1 |

Gear box drive |

|

Part 3 |

PLC control station |

set |

1 |

Delta brand |

|

Part 4 |

hydraulic system |

set |

1 |

For cutting |

|

Part 5 |

Product automatic stacker |

set |

1 |

6m length |

Hydraulic decoiler (You can choose 5 ton or 10 ton with loading car or without)

A. Supporting the coils and doing uncoiling. The capacity is 10 Tons(max).

B. It adopts the hydraulic oil cylinder to make the decoiler expandable and fit to the inner diameter of coils. It is equipped with the cantilever.

C. Motor drive the coils running and can do forward and reverse running as well as do the decoiling with tension.

Main rolling forming machine

Rolling number: 22 stations for profile (separated mold rolling)

Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in

good shape and high precision.

Work speed:0-45 m/min

Machine structure:Iron casting Vertical arch frame structure

Machine basic frame:Hot rolled H-beam. We will make diagonal bracing inside the frame, to strength the structure and keep the whole plate in same horizontal plane

After the whole welding, vibration is used to weld the stress. After large-scale planer machining, the horizontal and rigidity of the frame are ensured.

Bearing:Chinese famous brand Harbin

Work power:7.5kw two motors so total power 15kw

Why it can working in the speed of 45 meter per minute?

3.Molding frame with gearbox transmission, so even if in high speed, it can be quite steady.

Here is the high speed corrugated roof sheet making machine working video for your reference:

<iframe width="560" height="315" src="https://www.youtube.com/embed/Z5goS3MkmVs?rel=0" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" allowfullscreen></iframe>