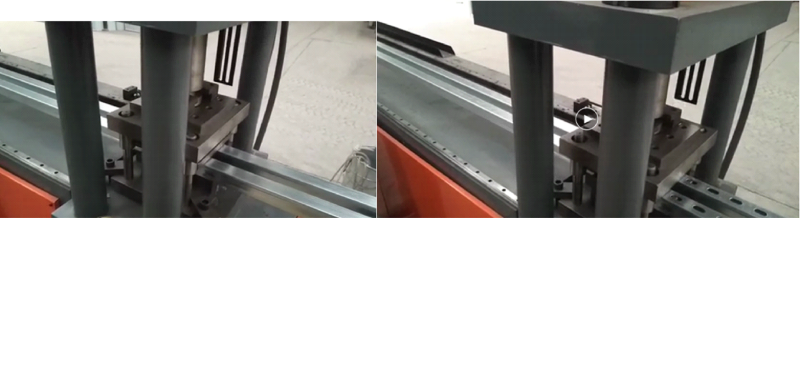

Offline punching means we do the rolling forming first and then do the punching separated. It is good for speed and lower cost but it needs more workers to do this.

Each time can do the punching two pieces. Also it can make sure the hole will not be stretched out.

We can design the machine fully according to your requirement.

Some reasons of effecting the machine cost

• 1.Decoiler manual or hydraulic with loading car or not.

• 2.Punching machine, normal brand or Chinese famous brand or world famous brand, which speed you need.

• 3. Main machine , transmission, gearbox or chain.

• 4. Machine motor, Siemens or normal brand.

• 5. PLC, Siemens or Delta

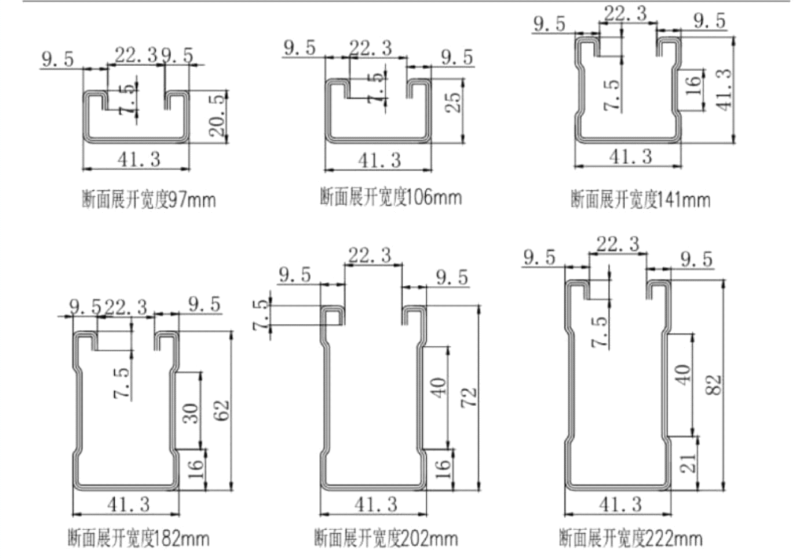

As to the rolling forming machine of Solar panel mounting bracket profile, here are some parameters for your reference:

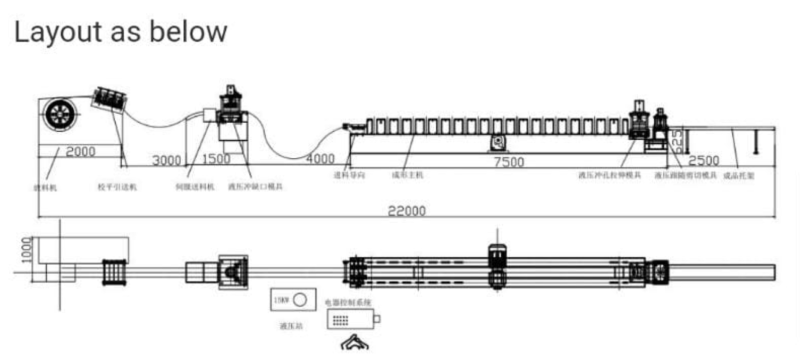

Main forming machine of Solar panel mounting bracket profile machine:

1) Forming steps: 28 steps

2) Outer diameter: 80mm

3) Machine frame (type): pillar frame

Thickness of memorial arch frame: 30mm

4) Roller information:

5) A. Raw material: GCr12MoV

B. Quenched degree: 56-58°C

5) Shaft material: 45# steel with heat treats and hard chrome plated on the surface

6) Main motor power: 18.5kw, Reducer ratio: 1:14,Reducer Type: Hardened reducer

7) With cooling device

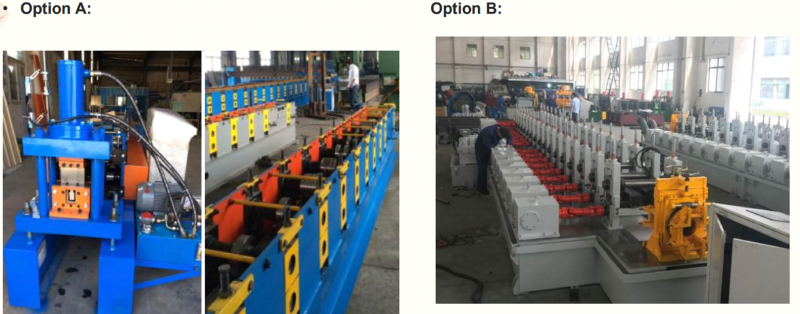

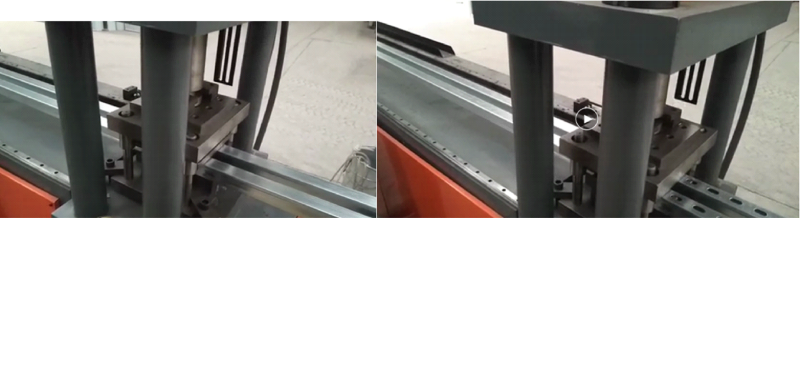

Machine Photo