Toggle Navigation

A hollow metal door frame is a type of door frame constructed from steel that has been formed into a hollow profile. This design provides structural integrity and durability while keeping the weight of the frame relatively light. Hollow metal door frames are commonly used in commercial and industrial buildings due to their strength and resistance to wear and tear. Here are some popular drawing profile for your reference:

Hollow metal door frames offer several advantages, including:

- Strength: They are very strong and can support heavy doors.

- Fire Rating: Many hollow metal frames are fire-rated and can withstand fire for a certain period of time.

- Security: The solid construction resists forced entry.

- Durability: They are resistant to warping, cracking, and damage from environmental factors.

-Customization: Hollow metal frames can be easily modified on-site to fit various door sizes and requirements.

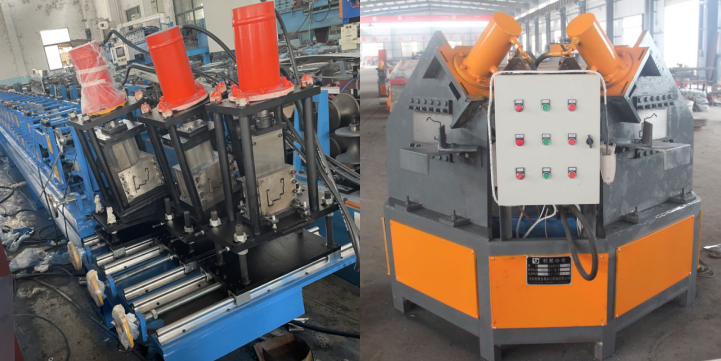

Based on those we make the metal door frame rolling forming machine either has the fully automatic and half automatic metal door frame rolling machine.

Metal door frame machine is a specialized piece of equipment used in the manufacturing process of hollow metal door frames. This machine is designed to shape or form steel strips or profiles into the desired shape of a door frame by a process called rolling.

The main features and functions of a metal door frame rolling machine may include:

This is the half automatic type: half automatic means there is no punching online for hinges holes, connection holes and lock holes. If you like the automatic type we could also make for you like the following pictures.

Here the door frame made by automatic door frame rolling forming machine:

We can design the machine fully based on your requirements but we need to know your drawing profile.

Take an example for the 45 degree shearing part, you can choose either online or offline. Also for the punching, you can also make based offline or online. For more information, you can contact me at any time.