Toggle Navigation

Open seam tube profile rolling forming machine is designed to make the tube profile in batch by rolling forming. As to the welding, you can choose to add or not. Meanwhile if you have special requirements about the seam, we can make for you also. For getting the accurate quotation, we need your help to give the following information:

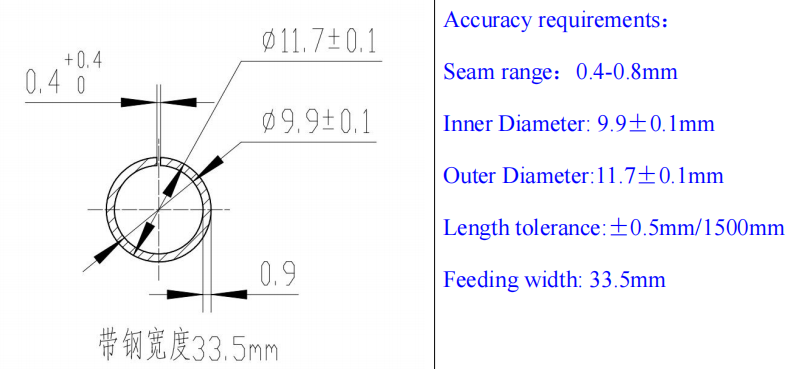

Here we take the following drawing profile for example:

Here the tubes for your reference:

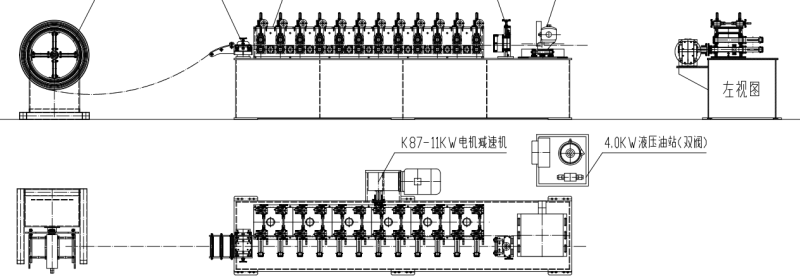

Open seam tube profile rolling forming machine:

Material : DC01 thickness 0.9mm Speed:10-15m/min

Testing machine: We sue width 33.5mm material testing the machine for customer.

The machine is composed by the following elements:

Part 1: 3T decoiler set 1 Manual

Part 2 Main roll forming machine set 1 10-15 m/min

Part 3 PLC control station set 1 Delta brand

Part 4 Cutting system set 1 Sawing cutting

Part 5 Product table set 1 Regular

Open seam tube profile rolling forming machine working flow:

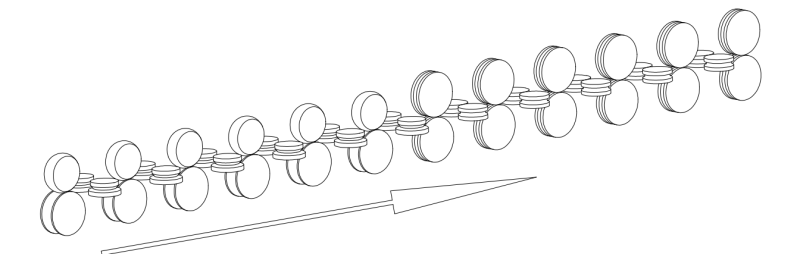

Open seam tube profile rolling forming machine roller design and working principle:

Cantilever structure tube roll former of this one we designed as for easy changing rollers in the future. And the machine will be more smart and take up small space. As to the shearing part, we design as disk shearing, no shape changing and more accurate.

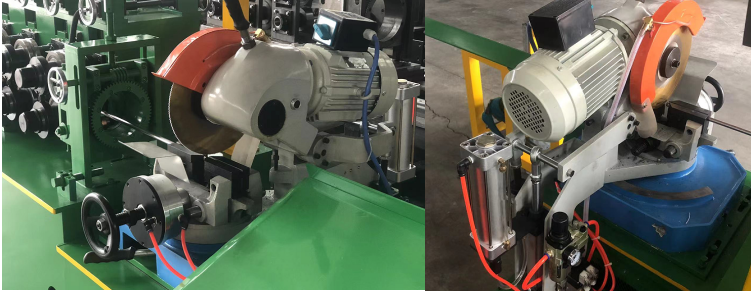

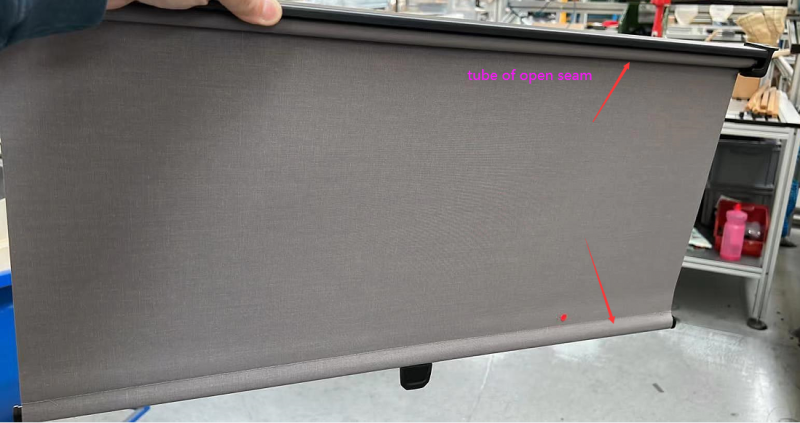

For the rolling forming machine, the accuracy we can control within 0.01mm. This machine we made for Italy and it is used as the curtain rail for car. Here are some usage pictures. So it will be super high in the accuracy control.

Open seam tube profile rolling forming machine working videos for your reference:

<iframe width="650" height="450" src="https://www.youtube.com/embed/2aDigEMnu_M?rel=0" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" allowfullscreen></iframe>